Fakuma 2017: Sought-After Shredding Systems by Lindner

Plastics recycling is gaining momentum. Lindner presented their innovative shredding and washing systems at this year’s trade fair for industrial plastics processing in Friedrichshafen, Germany.

Friedrichshafen/Germany, October 2017. Fakuma, previously a German specialist injection moulding fair, has developed into an international plastics exhibition. For the fair’s 25th anniversary, 1,889 companies presented their products and services in an 85,000-square-metre exhibition space in Friedrichshafen on Lake Constance from 17th to 21st October 2017. Many of the 48,375 who visited Fakuma from all over the world over those 5 days were not only interested in the latest moulding injection innovations but also in plastics recycling systems, as Marcel Willberg, Export Sales Manager at Lindner washTech (headquartered in Germany), noted: ‘The topic of plastics recycling is gaining momentum. There were more providers from the industry at the fair, attracting more customers who are interested in plastics recycling.’

What the market wants

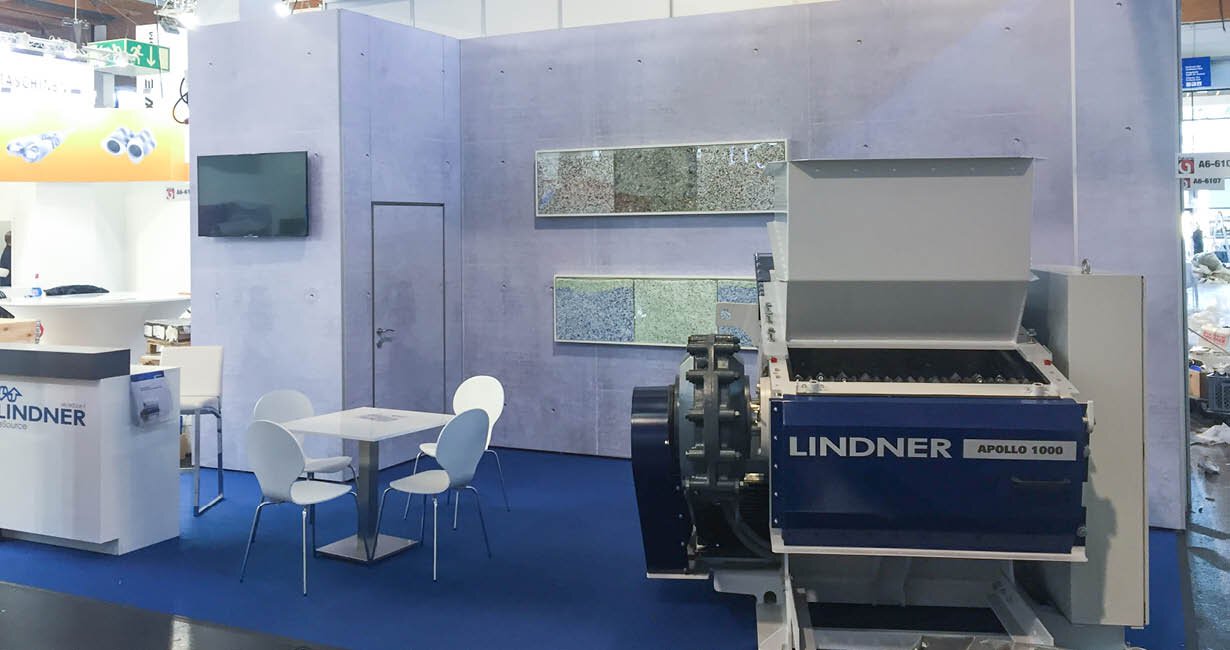

The high number of visitors was surprising. An Apollo 1000, a stationary universal shredder that reduces various types of product waste to a defined granulate size, was displayed at the Linder stand. In addition to the usual visitors from Austria, Switzerland and Germany, the Lindner team found that numerous potential customers from Eastern Europe also flocked to the stand. Many leads were registered and machines were sold directly to Germany and Eastern Europe; one Antares 1300 universal shredder was even bought by a customer from Israel.

Harald Hoffmann, Sales Director Plastics Division, welcomes the strong international demand for Linder processing systems: ‘Since the market for exporting plastics waste to China has as good as ground to a halt, the market is looking for new, innovative plastics recycling solutions. As a manufacturer of shredding technology, Linder has also proved successful on this market in recent years as a provider of efficient and compact plastics washing solutions’. Clean, high-quality, sorted recyclates allowing for better marketability – that is our goal.