Spittal/Drau (Austria), June 2022. Uniquely versatile, low maintenance & with an electric option – that’s Lindner’s new Urraco 4000 series. Available with a diesel or energy-efficient electric drive, its unique fast-exchange system (FX) and ease of access to the maintenance and drive compartment allow for maximum uptime. Its many mobile models and broad universal application satisfy every possible requirement and can handle all kinds of bulky waste, C&I, C&D and light scrap.

Around the world demand is increasing for the responsible and careful use of our resources – including energy. Machines and system solutions used in the waste and recycling industries, both mobile and stationary, play a key role. After all, it is only possible to recover valuable secondary raw materials from waste and recycling processes by using them. Lindner's mobile shredders are committed to achieving this in the most resource-saving and profitable way possible, keeping up the standards of energy efficiency, low maintenance, low operating costs, and reliably high throughputs for a wide range of input materials.

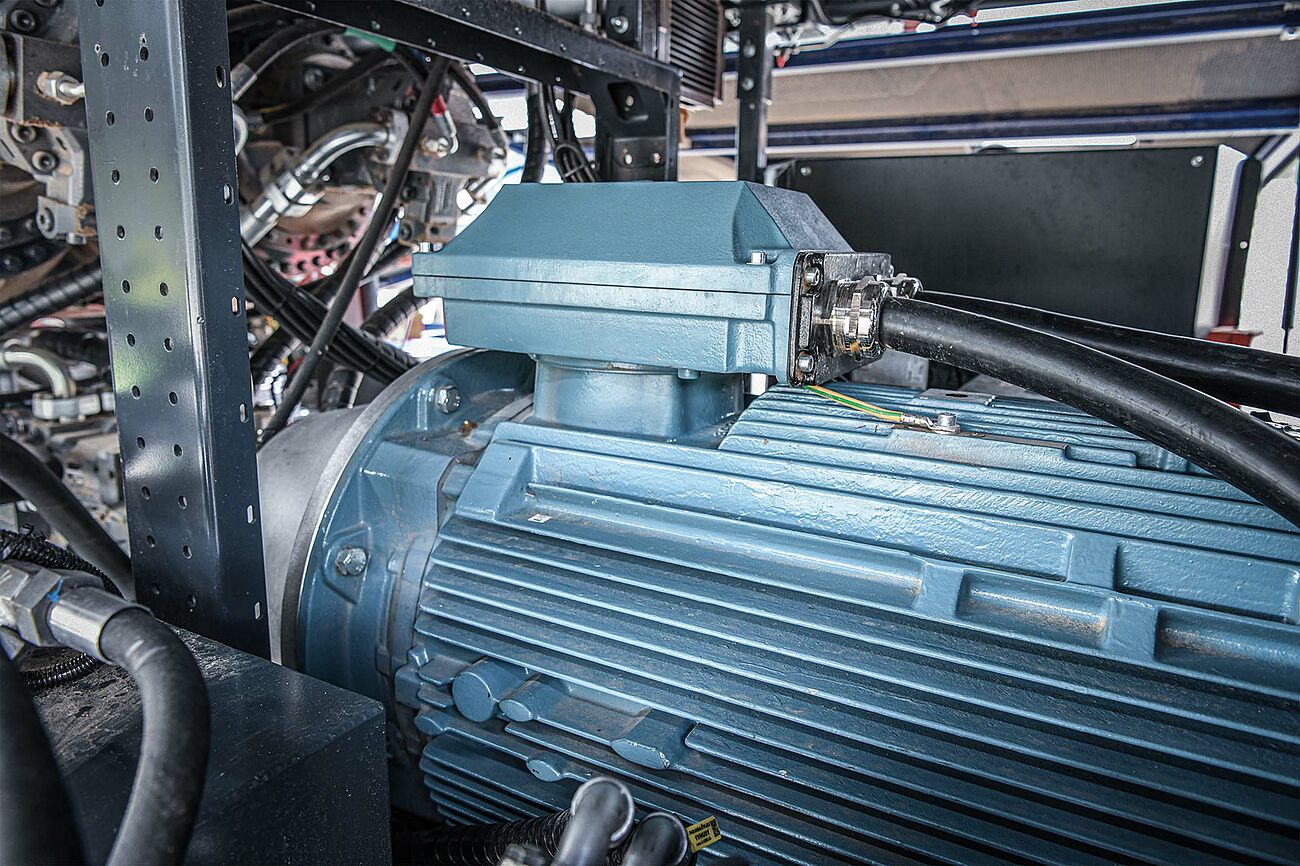

The new mobile shredder series Urraco 4000 with its 2000 shaft length bridges the gap between the Urraco 75 and the Urraco 95 shredder serieswhich have been industry favourites for years. The new Urraco 4000 series highlights include an optional energy-efficient E-drive with Powerlock quick connectors, a great variety of mobility options, such as a base frame, tracked chassis, or semi-trailer, and many features to make maintenance so much easier, including the shaft fast-exchange system (FX).

Always energised – the Urraco 4000 series E-models

The E-models of the Lindner’s new Urraco 4000 series go beyond EU requirements, providing CO2-friendly mobile shredding solutions for the global waste and recycling industry. Two things were vital while developing the two E-models that are either available with a base frame (Urraco 4000 E) or a tracked chassis (Urraco 4000 EK): energy efficiency and high performance. Moreover, it is incredibly simple to connect the machines to the grid via Powerlock quick connectors. In addition, the Urraco 4000 EK model's built-in self-sufficient power unit provides extra flexibility on site. This means that the shredder can be moved independently of the power supply

Powerlock quick connectors to quickly and easily connect to the grid

A complete system

In the realm of waste wood processing, the additional use of the also electrically powered Zeta Star 4000 E-screen, also electrically operated, ensures optimal particle sizes at all times. The resulting defined particles improves the capitalisation and the resale value of the output material, significantly optimising profits.

Low Maintenance & higher productivity

To improve uptime and throughput, high-performance shredders are required to have low operating costs, optimum feeding, and low maintenance. The models in the Urraco 4000 series fully rise to the challenge, allowing for easy access, for example, to the maintenance points and drive compartment. Should a shaft change be necessary, it can be carried out in less than three hours, thanks to Lindner’s unique fast-exchange system. The extended working area, which is created by combining the shaft length and the axle distance, enables smooth filling by a wheel loader. The optimised intake, combined with the patented twin-shaft cutting system, allows for efficient and easy shredding of bulky and large-volume materials. This makes it another essential cornerstone for high productivity.

Drive unit.The shredders of the model series Urraco 4000 are equipped with our known diesel drive, and are optionally available with energy-efficient e-drive (picture).

More Information | Press Contact:

Pia Steiner | pia.steiner(at)lindner.com