UNIVERSAL SHREDDING TO THE EXTREME:

ROBUST, RELIABLE AND HIGH THROUGHPUT.

1 | Maintenance door

The hydraulically operated, inward-opening maintenance door allows you to quickly and safely access the cutting system for maintenance work or swiftly remove foreign objects with minimum material leaks.

- REMOVE FOREIGN MATTER QUICKLY AND CLEANLY with the maintenance door at position 2

- ENJOY COMFORTABLE MAINTENANCE ACCESS to the knives and counter knives with the maintenance door at position 3

- 100% SAFE OPERATION with the mechanical safety lock and the pusher's special parking position

2 | Heavy duty gearbox drive

Universo’s tried-and-tested, extremely sturdy drive offers high torque values and excellent performance. Designed for continuous operation, the motor and gearbox ensure that the rotor cutting system rotates 150 times per minute at a nominal capacity of 220 kW.

- POWERFUL SHREDDINGthrough powerful motors with high torque

- INDIVIDUAL ADAPTION to the material through variable speeds

- WORLDWIDE AVAILABILITY of the easy-to-change standard components

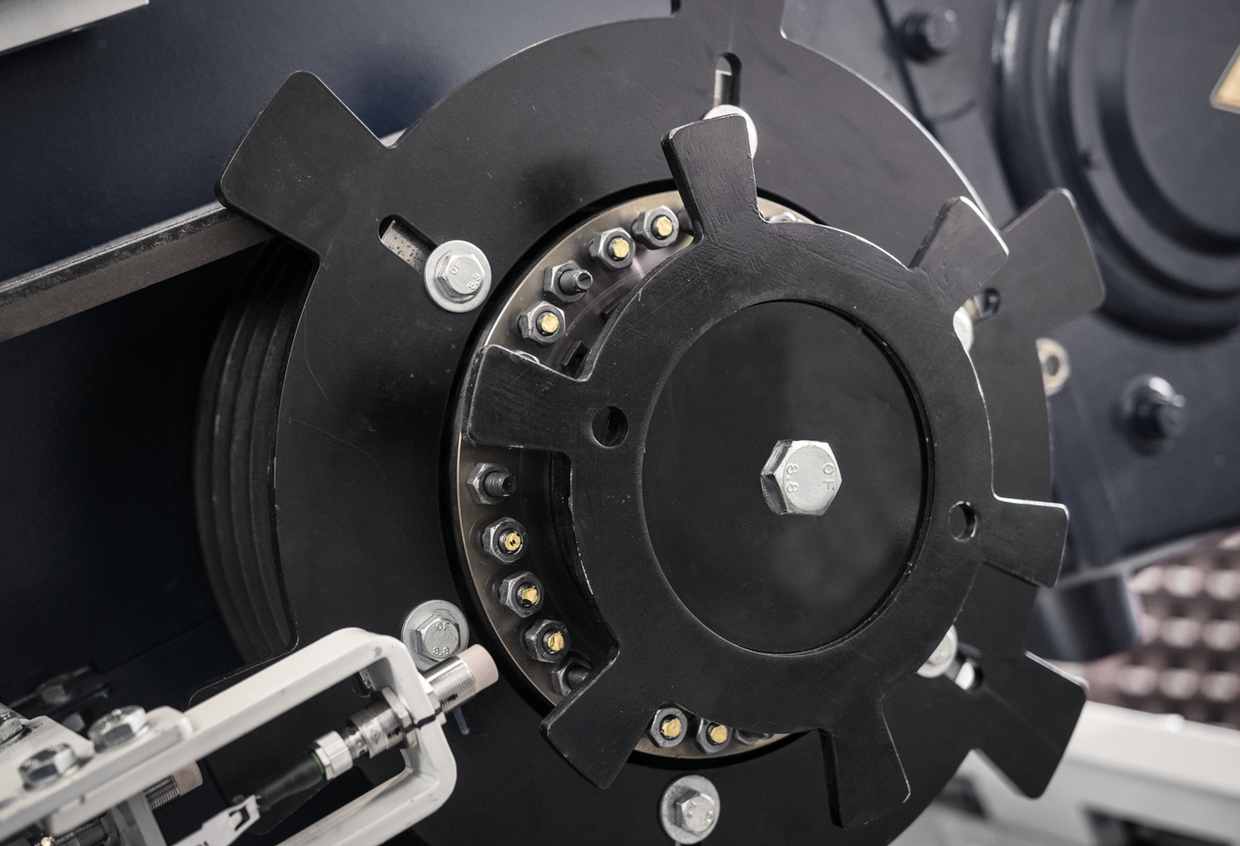

3 | Safety clutch

The torque-limiting clutch protects against damage to the drive unit when blockages are caused by foreign objects. Furthermore, the highly precise sensors facilitate the controlled powering down of the machine to preserve all components.

- PERFECT DRIVE PROTECTION thanks to the drive unit’s lightning-speed disengagement

- SECURE POWER DOWN with robust sensors

- FULLY ADJUSTABLE to various materials

4 | Internal pusher

Lindner's original: tried and tested a thousand times over, our internal pusher allows for easy and secure machine feeding. Our years of experience and continuous development have left their mark on its distinctive design.

- CONTINUOUS SHREDDING due to smooth feeding

- EASY FEEDING with a completely internal construction

- MAINTENANCE-FREE thanks to the absence of guide elements

- NO JAMMING as a result of additional comb and sealing bars

5 | Cutting system

ROBUST SQUARE CUTTING SYSTEM

Specifically made for the toughest conditions: these particularly robust cutters and cutter holders make the cutting systems impervious to foreign objects, resulting in a long service lilfe and high output rates. The double cutting counter knives and scrapers as well as the cutting gap that is adjustable during operation let you enjoy continuously high output rates for consecutive processes.

- HIGH OUTPUT RATES even with tough materials

- LOW WEAR AND TREAR COSTS ensured by fourfold usable, quick-change cutters

- UNDETERRED BY NON-SHREDDABLES thanks to robust knives and knive holders

6 | Plug & go screen unit

The swivel-mounted, hydraulically operated screen unit allows for easy and comfortable access for maintenance and refitting. The screens are available with various mesh widths and can easily be changed by hand by just one person – so you can quickly customise the shredder to the particle size you need.

- EASY ACCESS FOR MAINTENANCE AND FITTING thanks to the swivel-mounted, hydraulically operated design

- FLEXIBLE OUTPUT SIZES made possible with our screen units in various hole sizes

- EXTREMELY SAFE OPERATION with the electromagnetically locked screen access point, preventing access to the cutting chamber while the machine is in operation

Fire prevention

THAT’S HOW TO PLAY IT SAFE

Lindner’s modern out-of-the-box FPS solution automatically detects and cools over heated particles in the material stream directly on the discharge conveyor, effectively preventing possible sources of fire. The system adapts the cooling process to the hazardous situation to ensure the facility operates optimally at all times.

- Precise detection of overheated materials

- Comprehensive monitoring of the entire cooling section

- Cooling process adapted to the hazardous situation

- Independent cleaning of the infrared sensors

- Temperature resistant and robust thanks to a special insulation system

- Highly flexible modular design

Watch video here!

Water sprinkling system

- To remove dust from the filling area

- 4 spray nozzles positioned in the enclosed hopper

- Switch it ON/OFF using the control panel

- Machine piping incl. central water supply

- Incl. heating system & piping insulation

Find your ideal solution and

Connect with us

INPUT & OUTPUT MATERIALS

FILM

HDPE Plastics

MSW

bulky waste

| Universo 2200 | Universo 2800 | ||

| Dimensions* | |||

| Measure (LxWxH) | mm | 6000 x 2900 x 3950 | 7000 x 2900 x 3950 |

| Hopper opening (DxF) | mm | 3985 x 1600 | 4675 x 1600 |

| Feading height | mm | 2960 | 2960 |

| Capacity | m3 | 3.7 | 5 |

| Outlet width (I) | mm | 840 | 840 |

| Total weight | t | 18 | 27.2 |

| Cutting Unit* | |||

| Length | mm | 2115 | 2805 |

| Speed | min -1 | 80 | 80 |

| Standard tool | pointed knives 43P | pointed knives 43P | |

| Number of knives | pcs. | 138 | 186 |

| Number of screens | pcs. | 4 | 6 |

| Final output | mm | 20 – 600 | 20 – 600 |

| Drive* | |||

| Typ | gear drive | gear drive | |

| Motor | kW | 1 x 132 | 2 x 110 |

* The stated values refer to standard machine versions with a standard hopper and raised feet. The right to make technical changes is reserved.