New Micromat Series IV.

Energy efficiency meets maximum material versatility

At the heart of the new Micromat series is an energy-efficient drive concept of the latest generation with an efficiency rating of 97%. Also new is the adaptable rotor concept, which allows for a quick change between pointed and blade knives, ensuring maximum flexibility for different materials.

An easy cutting gap adjustment, a new coupling design, effective counter-knife cooling, intuitive menu navigation, and patented automatic belt tensioning complete the new shredder series.

Connect With Us

Need answers about applications or particle sizes? Reach out today - our specialists are ready to provide support. Together, we'll uncover your perfect solution.

Input & Output Materials

Lindner Advantages

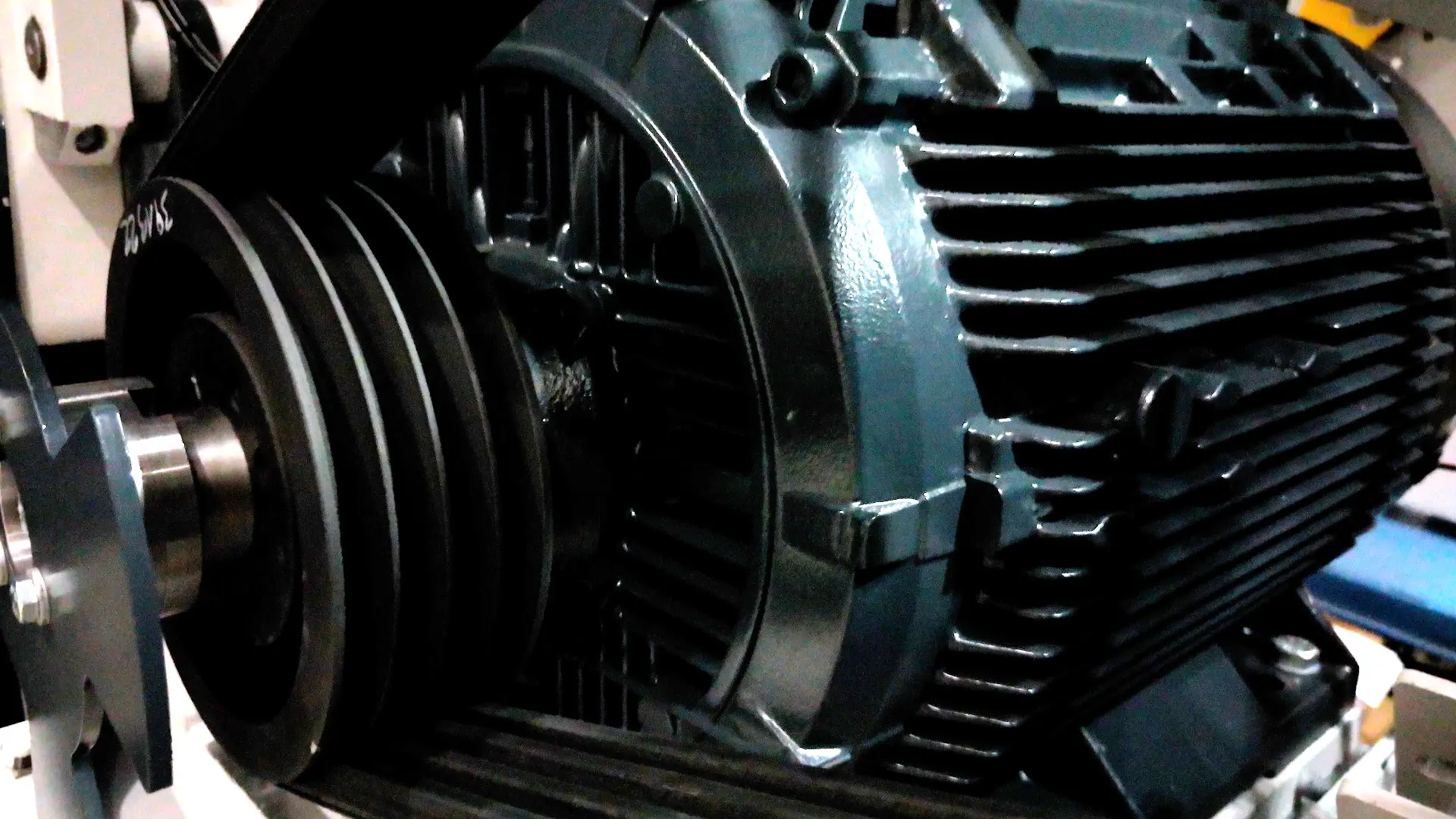

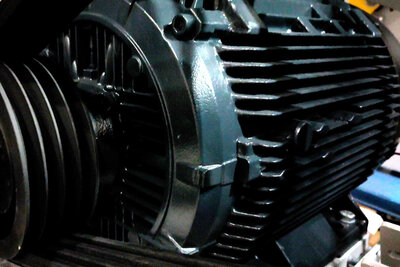

High-Efficiency IE6 SYNRM motor

HIGH-EFFICIENCY IE6 SYNRM MOTOR

The synchronous reluctance motor offers several advantages:

- It is more efficient than asynchronous and torque motors.

- Significantly lower energy losses compared to comparable asynchronous motors.

- Lower winding and bearing temperatures, leading to a longer lifetime.

- No rare earth elements (magnets) are required in the production.

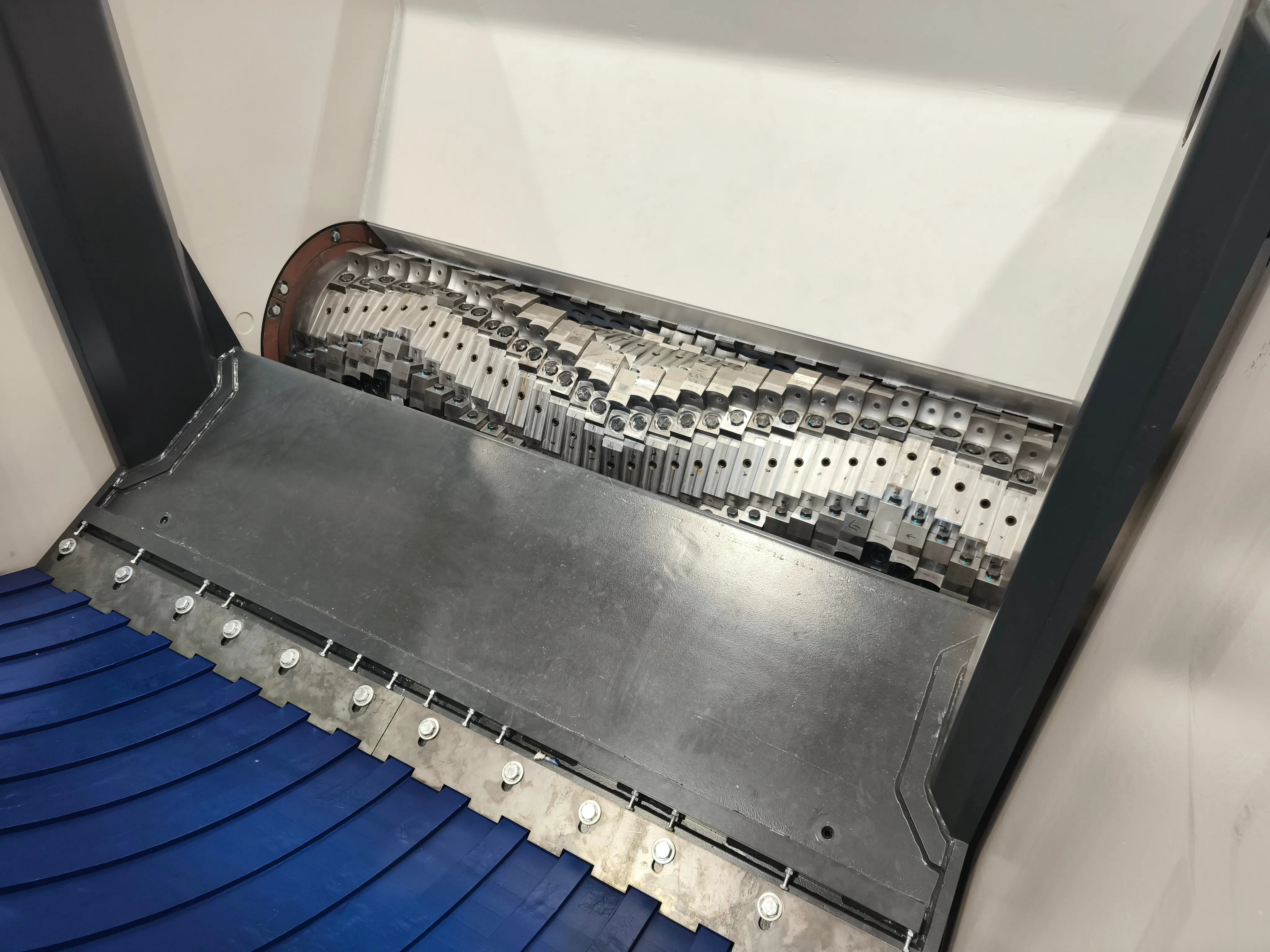

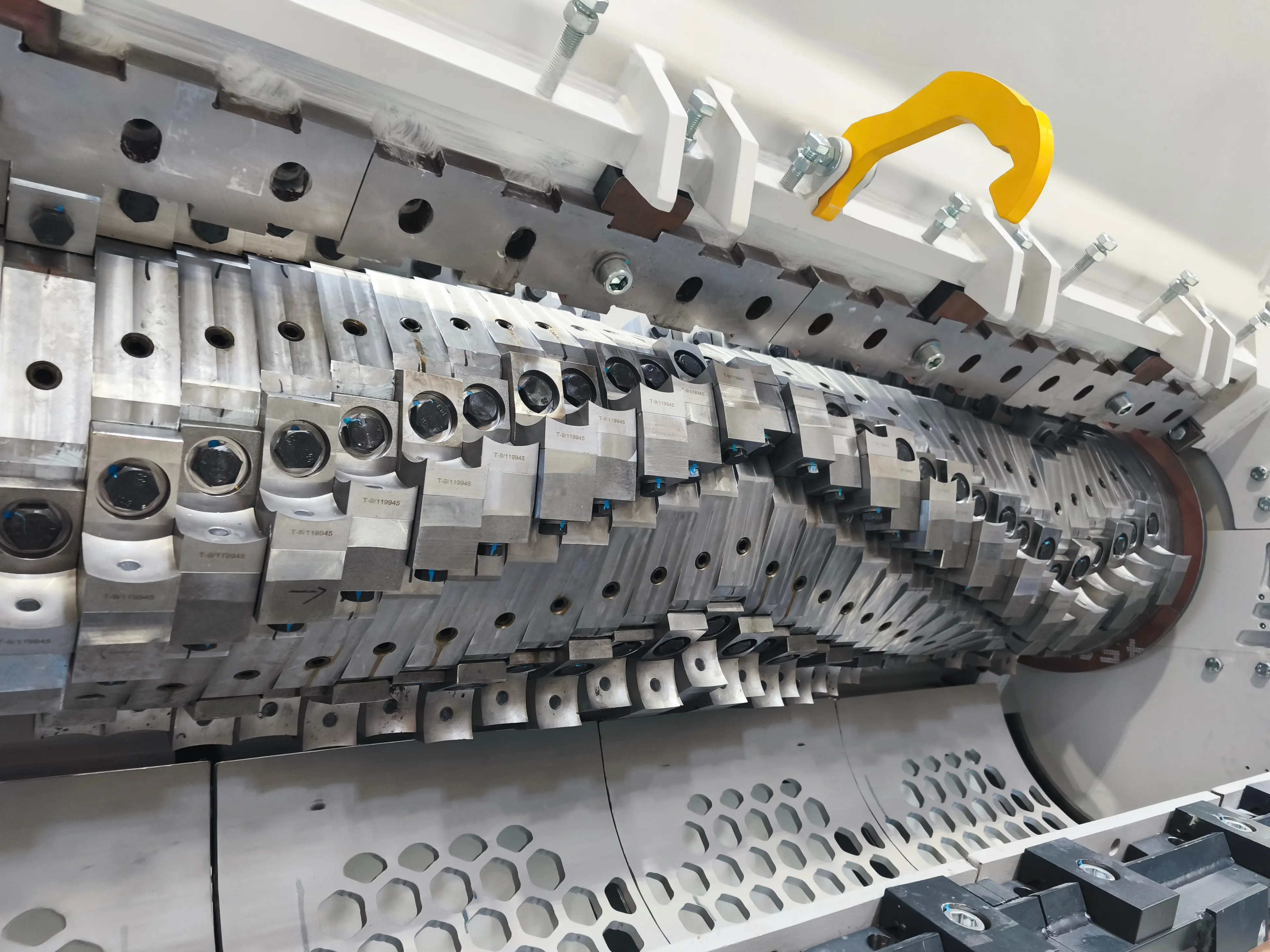

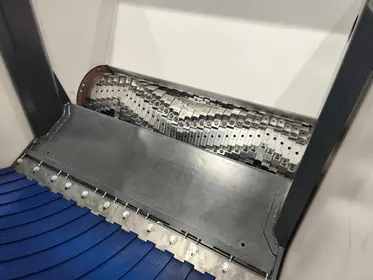

Multicut Rotor

One Rotor - different knife configurations (option)

The new rotor was designed for customers who process many different materials. The different, screw-in knife systems can be easily swapped at any time without having to replace the entire rotor.

- no needs to be hard-faced - the worn parts can be easily replaced.

- Up to 40 percent higher throughput for film.

- The cutting gap between the counter knives and rotor knives can be easily adjusted from the outside.

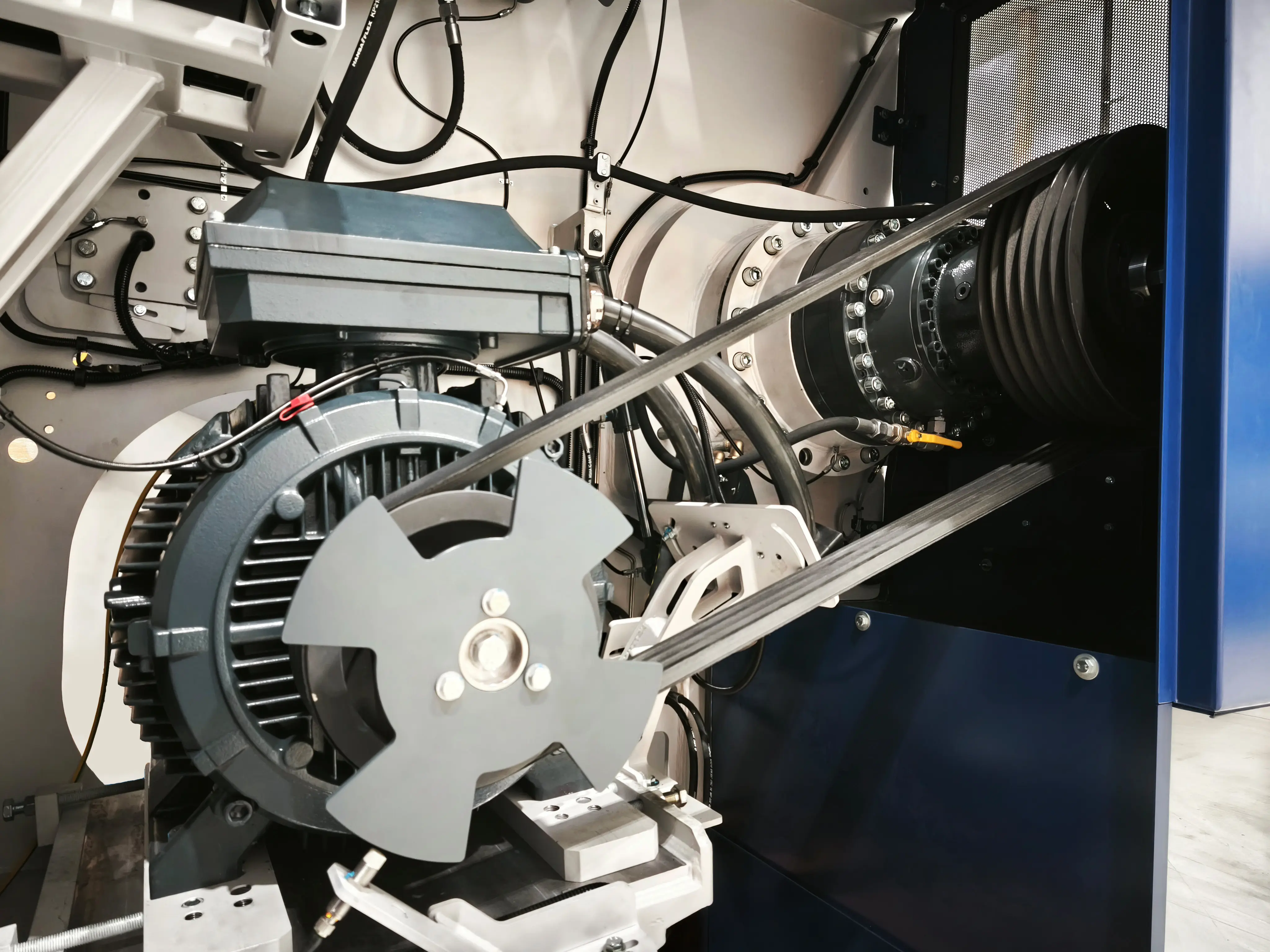

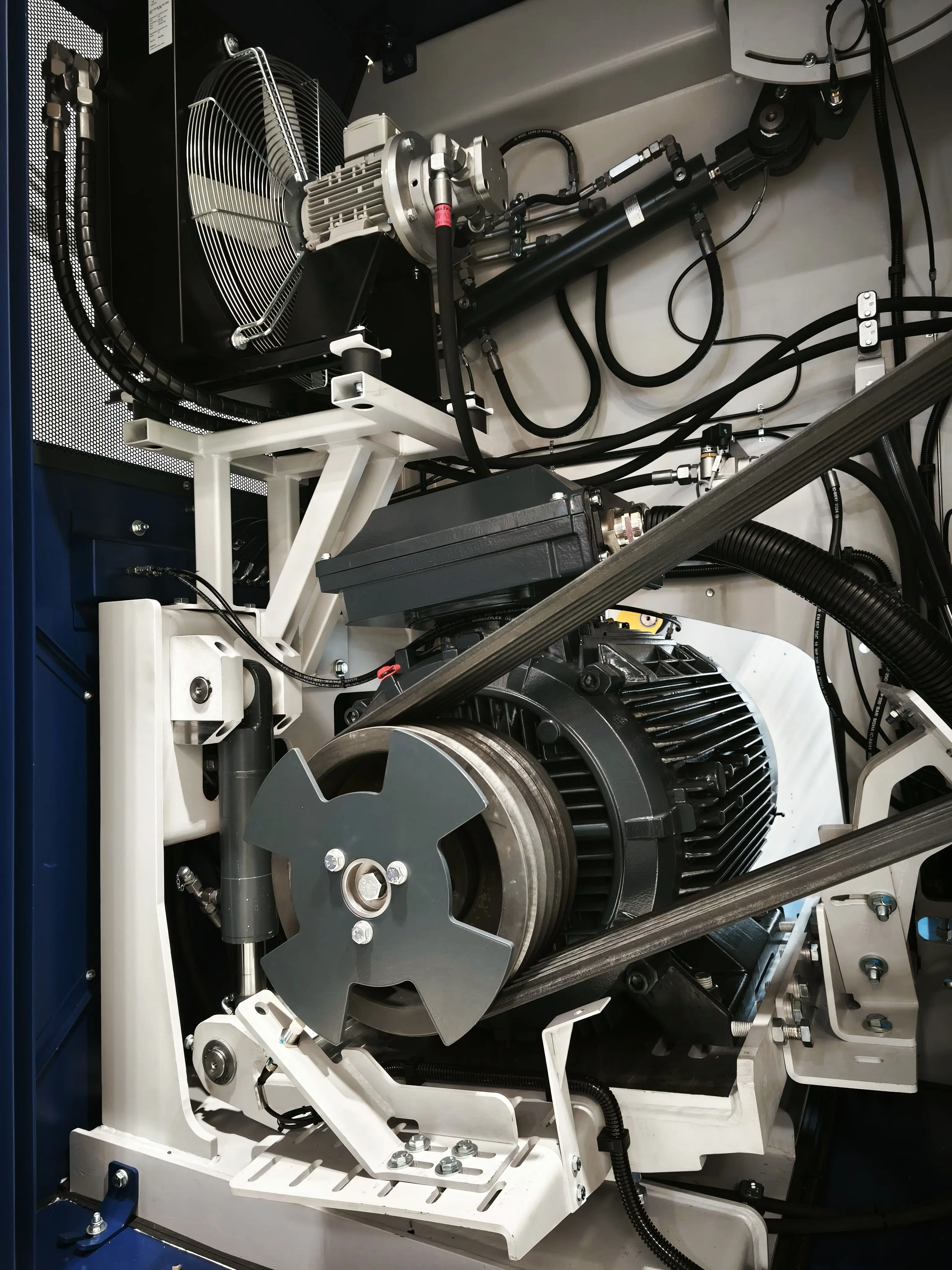

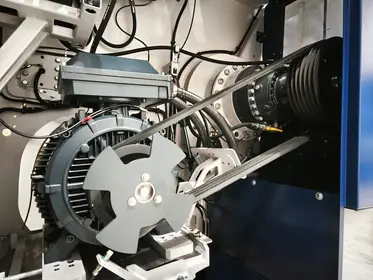

ATB / belt-drive safety clutch

ATB / belt-drive safety clutch (option)

The maintenance-free drive system ensures optimal belt tension at all times for maximum performance and allows quick, tool-free belt replacement via hydraulic cylinder.

- The drive belts are automatically tensioned to the optimum level by means of the hydraulic cylinder.

- If a foreign part is detected, the pressure is released from the hydraulic cylinder.

- The pulley turns freely in the belts.

- No additional safety clutch is required

- Fully automatic running-in program during belt replacement to ensure the belt fits perfectly.

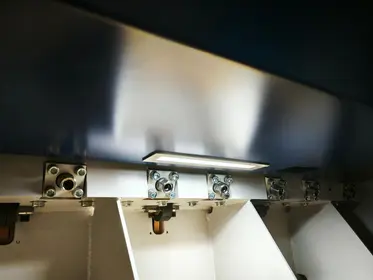

ADJUSTABLE COUNTER KNIVES

ADJUSTABLE COUNTER KNIVES & MAINTENANCE LIGHT

- Quick adjustment of the cutting gap without having to open the maintenance door.

- The counter knives are clamped from below with screws.

- Thanks to the knife slide, the counter knives can be moved forwards and backwards with the same screw.

- The light in the maintenance door provides the best visibility inside and around the cutting chamber.

Mono Fix Technology

The Mono Fix system allows knives and knife holders to be changed with just one screw. A combination of different pointed and flat knives, as well as blind plates and special counter knives, can also be attached to the rotor. The result:

- Maximum flexibility of the cutting unit

- Maximum adaptation to input and particle size