KOMET 1800 | 2200 | 2800

Unbelievably Precise.

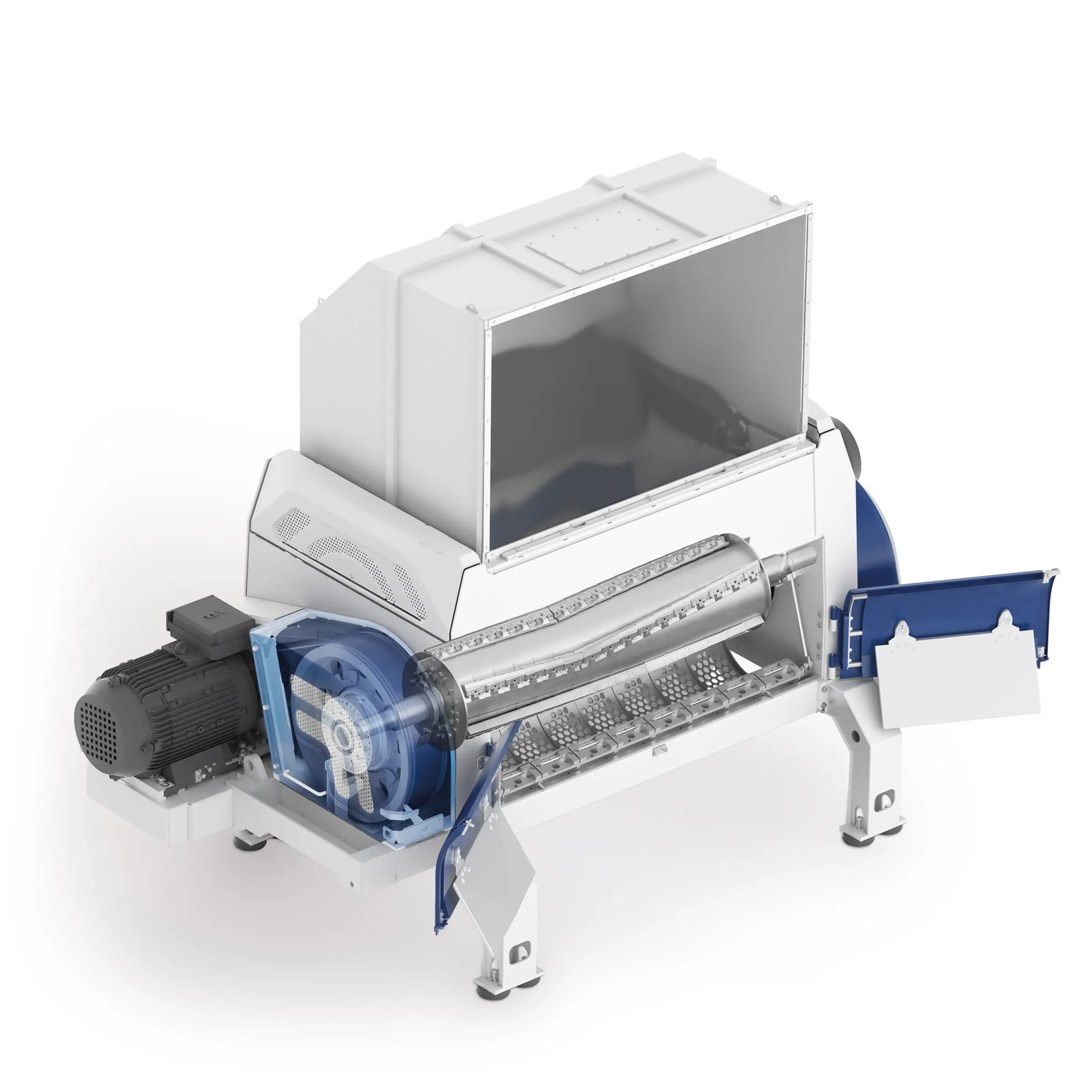

Single-Shaft Secondary Shredder For 24/7 Premium SRF Production:

Precision That’s a Cut Above the Rest.

The Lindner Komet sets new standards in single-shaft shredding. Whether you are processing municipal or bulky refuse, industrial or commercial waste, textiles, waste paper or other materials – the Komet ensures smooth processes 24/7 thanks to its robust design, high-precision tools and smart features. Benefit from its first-rate particle quality and superb efficiency.

Find Your Ideal Solution And

Connect With Us

Need answers about applications or particle sizes? Reach out today - our specialists are ready to provide support. Together, we'll uncover your perfect solution.

Input & Output Materials

Key Features

Lindner Advantages

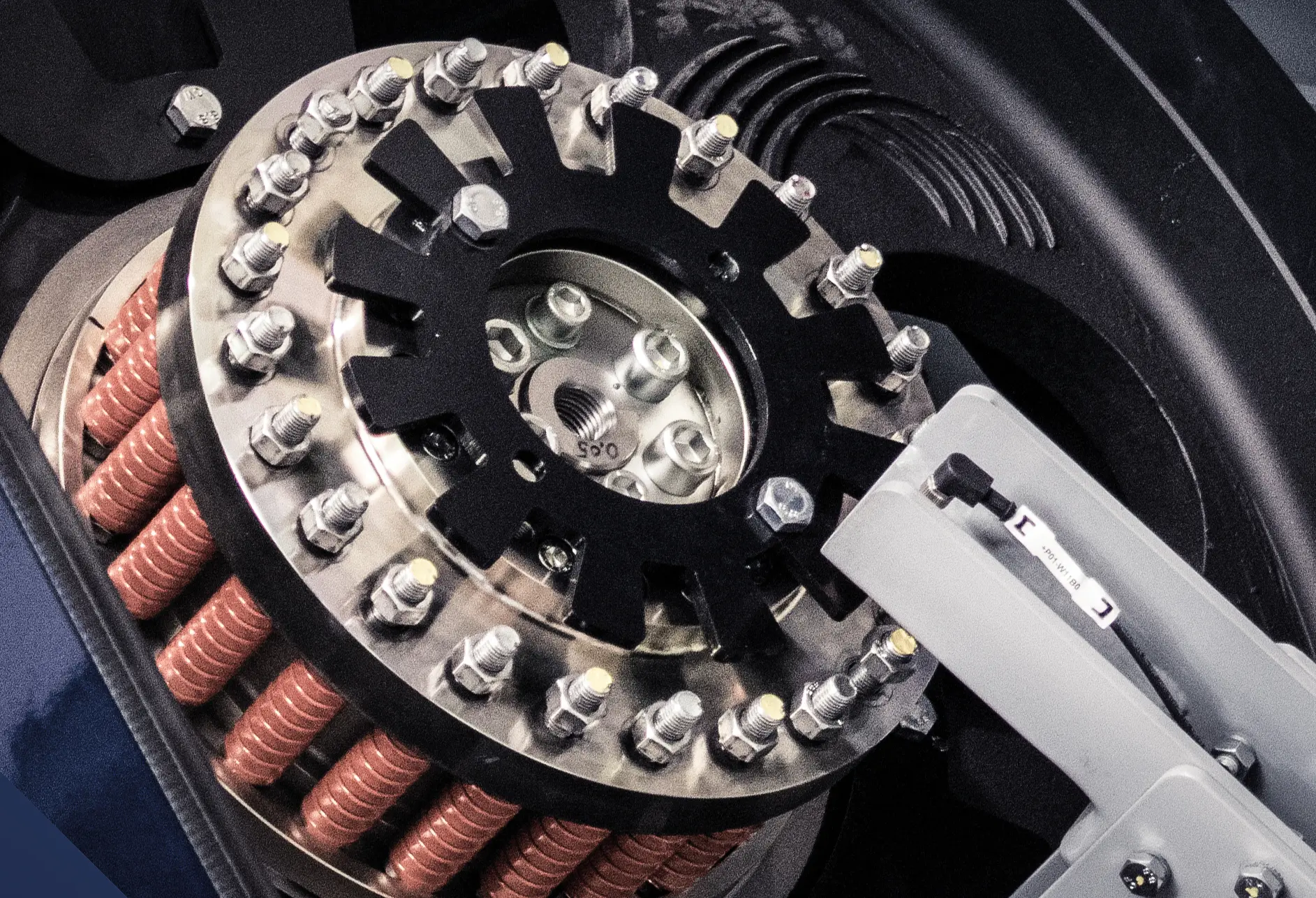

Precise Rotor with Square Knives

- High throughputs guaranteed thanks to the strategically positioned knife rows

- Consistent particle size with a cutting gap that is fully adjustable even during operation

- Optimised wear parts storage thanks to identical knives for the rotor, counter knives and scraper

- Maximum uptimes ensured by four-fold usable, quick-change knives

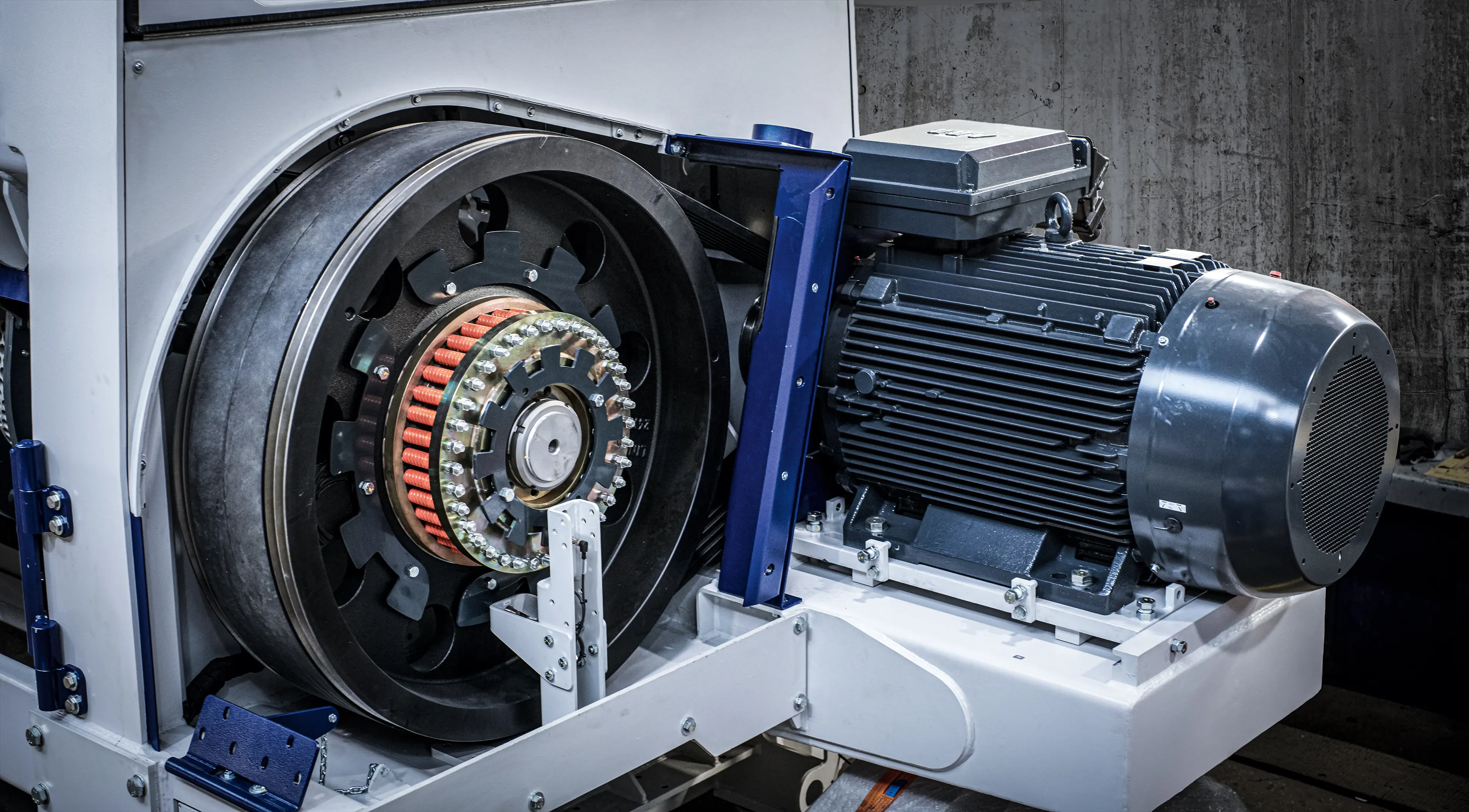

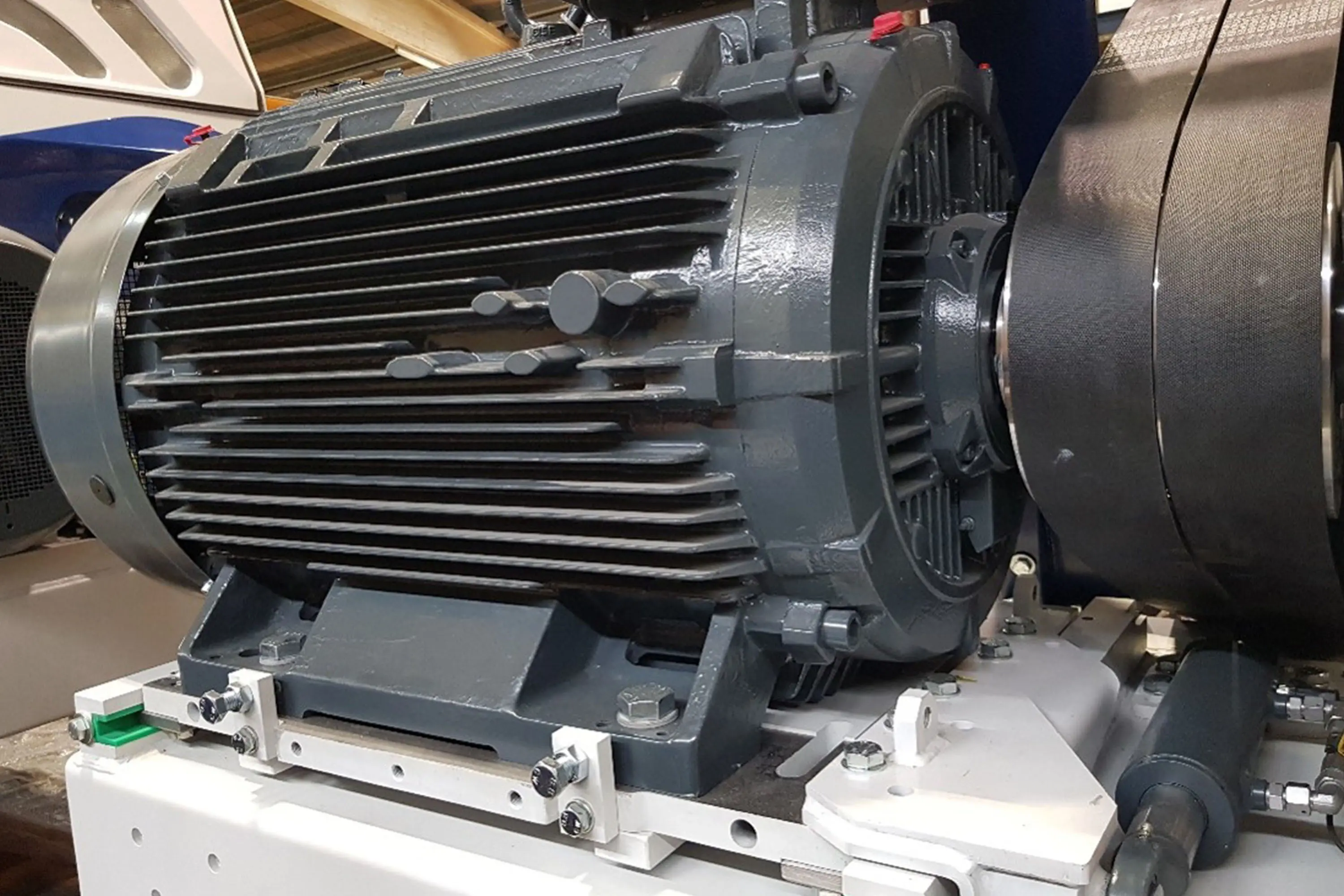

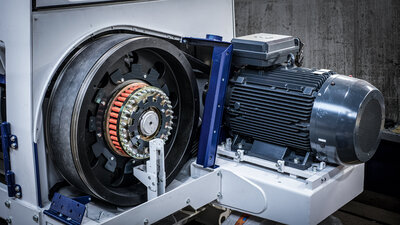

Tried-And-Tested Belt Drive

- Efficient, robust and gearless belt drive

- Worldwide availability of easy-to-change standard components

- Mechanical safety clutch for maximum resistance to non-shreddables

- HP (high performance) option for even higher productivity

- Optional: Comfort function for automatic belt tensioning