MAXIMUM PERFORMANCE.

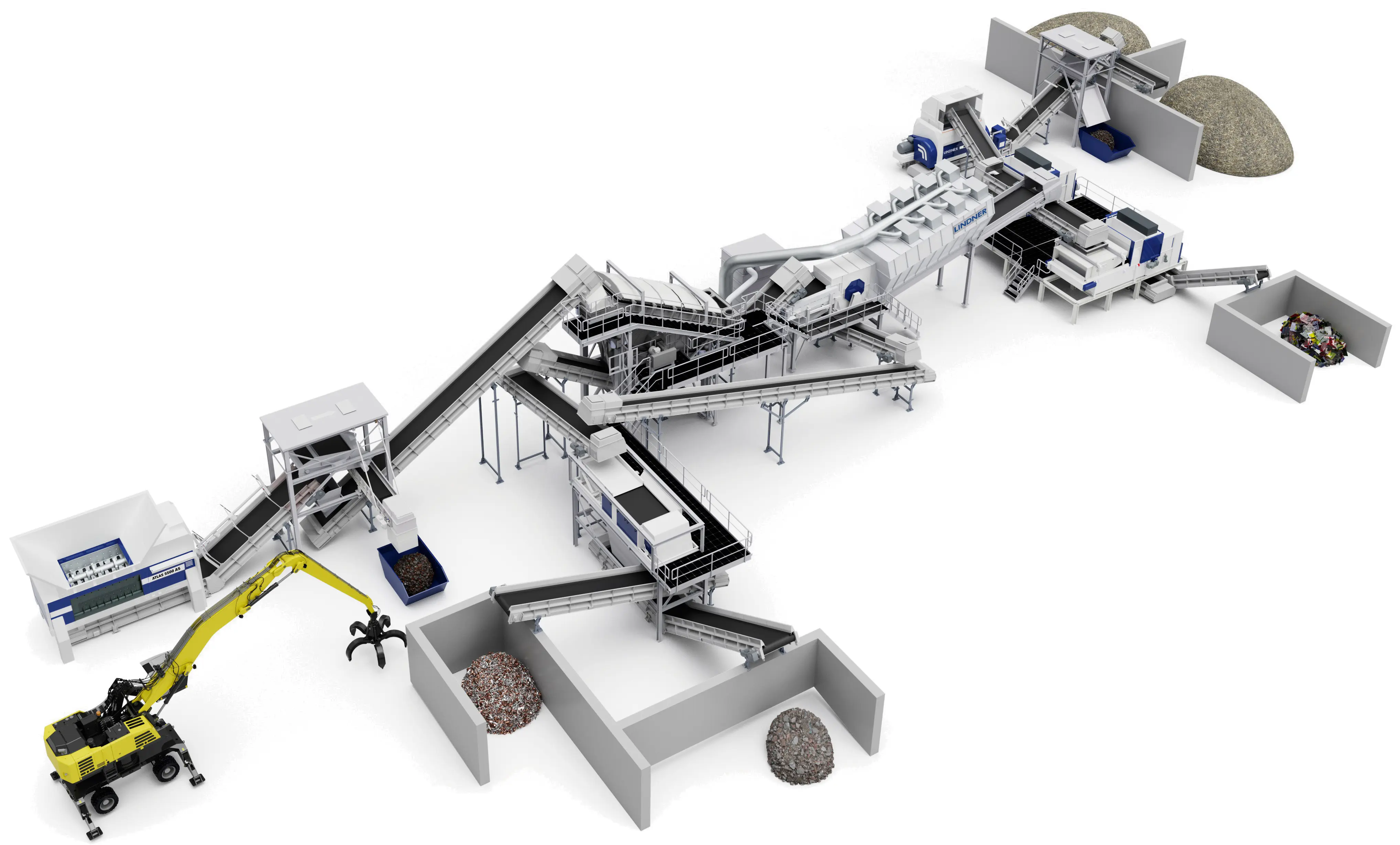

Lindner has perfected the multi-step processing of mixed municipal solid waste, commercial waste and industrial waste into a high-calorific premium solid recovered fuel. An ideal combination of high-end machines is responsible for primary and secondary shredding as well as efficient separation and extraction, making SRF processing almost maintenance-free, extremely robust and reliable. The resulting SRF is free from non-shreddables such as metals, stones or glass – guaranteeing the highest throughput and maximum output quality. Thanks to NIR technology, analysers digitally analyse the material in real time, ensuring the output material’s optimum calorific value. Optical sorting equipment also makes use of this technology to extract recyclables such as plastics from the material stream and return them to the recycling process.

Connect With Us

Need answers about applications or particle sizes? Reach out today - our specialists are ready to provide support. Together, we'll uncover your perfect solution.

TURN WASTE INTO A VALUABLE RESOURCE.

Premium solid recovered fuels (SRF) are mainly used for co-incineration in the main burners of rotary kilns and contribute to conserving fossil fuels. To be a valid alternative to primary fuels such as oil, coal or gas, the solid recovered fuel must fulfil many quality criteria. A particular challenge is posed by the differently composed input materials that have to be transformed into a highquality, homogenous output. State-of-the-art inline sensors are used to consistently control the parameters that are most important for the production of SRF – including, for example, calorific value, water, ash and chlorine content.

Requirements for high-calorific solid recovered fuels

| Particle size | d95 ≤ 30 (up to 35) [mm] |

|---|---|

| Calorific value | 18 – 25 [MJ/kg] |

| Density | < 150 kg/m3 |

| Moisture content | < 15 % |

The exact requirements may vary depending on the design of the cement kiln.

Materials