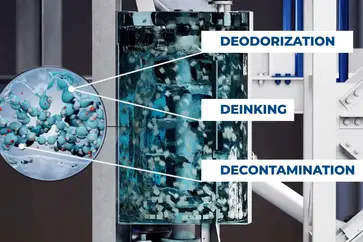

Spittal an der Drau, Austria. June 2025. At the K 2025, Lindner will be making the most of its exhibition space – spread across Hall 9, Stand B17/19, and the outdoor area CE02 – showcasing trailblazing technologies and new products to process waste plastics. The spotlight will be on first-class recyclate quality, energy efficiency, maximum flexibility, smart process optimisation along the entire value-added chain, and – a world first in mechanical recycling.

Ready for the future of your business – This is the motto underpinning the groundbreaking technologies and innovations being exhibited by recycling pioneer Lindner at the K 2025, including a revolutionary world first in mechanical recycling. Visitors will also see the new fourth-generation Micromat, whose smart technology sets new standards in energy efficiency and material flexibility. The joint venture between Lindner Washtech and EREMA is an impressive example of the impact of holistic process optimisation – from bale to pellet – of guaranteed recyclate quality, throughput and resource utilisation.

Ready for energy-efficient versatility – the fourth-generation Micromat

For the new Micromat series, Lindner has built on the proven strengths of Series 3, adding upgrades that improve both maintenance and productivity. The core of the new shredder series is the innovative drive concept that features a remarkable level of efficiency of above 97 %. Unlike a torque drive, the new concept operates without any rare earth elements and has an impressively long lifespan. Another highlight is the flexible, configurable blade system. This makes it possible to quickly replace pointed knives with step knives – which enables the shredder to flexibly adapt to different material requirements.