THE CYCLE STARTS HERE.

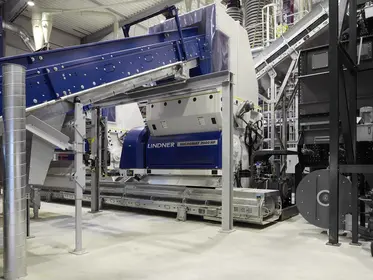

Quality right from the start. Optimum sorting is an important part of a plastics recycling facility – the higher the sorting quality and the purity achieved, the better the final output granulate. At the beginning of the process chain, the Lindner shredder opens the bales. Specially optimised for the downstream NIR sorting system, the throughput is uniform and has few fine particles. Thanks to NIR sorting devices as well as various processing stages and additional units such as metal separators and screening technology, it‘s possible to transform waste streams into pure quality, which is then fed into downstream plastic washing systems.

Success All Along the Line.

Lindner’s multi-stage washing lines are in a class of their own. Perfectly matched components ensure superb output quality. Robust high-tech shredding, washing and drying processes are the key to a smooth 24/7 operation with low maintenance requirements and consistently high throughputs. It has never been easier to guarantee the ideal input for subsequent processes. Based on this standard solution, Lindner‘s washing facilities are individually adapted to the respective requirements. The additional installation of a hot-wash unit ensures that the output material meets the highest quality specifications.

Connect With Us

Need answers about applications or particle sizes? Reach out today - our specialists are ready to provide support. Together, we'll uncover your perfect solution.

Circular Economy

Zero Waste Potential

Lindner’s plastic recycling solutions are all the rage: thanks to an ever-increasing demand for polymers and the worldwide desire to use valuable resources more efficiently, higher-quality recyclates are highly sought after. The key to meeting these quality requirements is to prepare the material to be recycled as well as humanly possible.

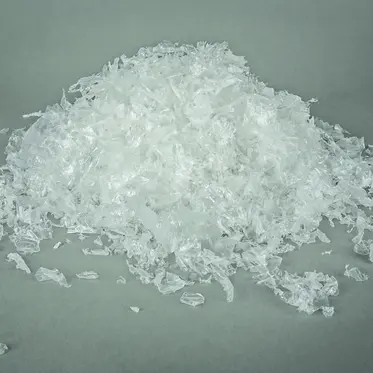

End product characteristics

| Particle size | < 50 mm |

|---|---|

| Moisture content | 5-8% |

| Materials | PP, PE, PE-HD, PE-LD, PE-LLD, etc. |

Post-Consumer Plastics Recycling

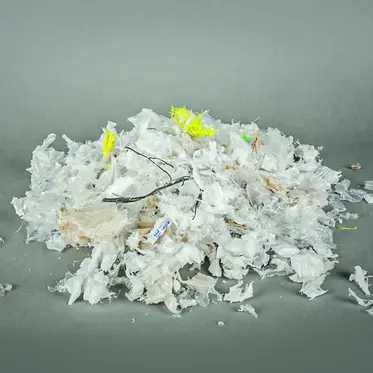

Post-consumer waste is created by consumers, e.g. individuals and households. The field of post-consumer plastics in particular demands high machine standards since the material might not only contain abrasive matter but also food scraps. The foreign object-resistant shredder and the high-end washing technology ensure a homogeneous product ready for extrusion. Manufacturing companies can then turn the resulting lenticular plastic raw materials into the final product. Waste is transformed into a new product, saving energy and resources.

Input & Output Materials