Universo 2200 | 2800

Bites Through Everything.

Universal Shredding To the Extreme:

Robust, Reliable and High Throughput.

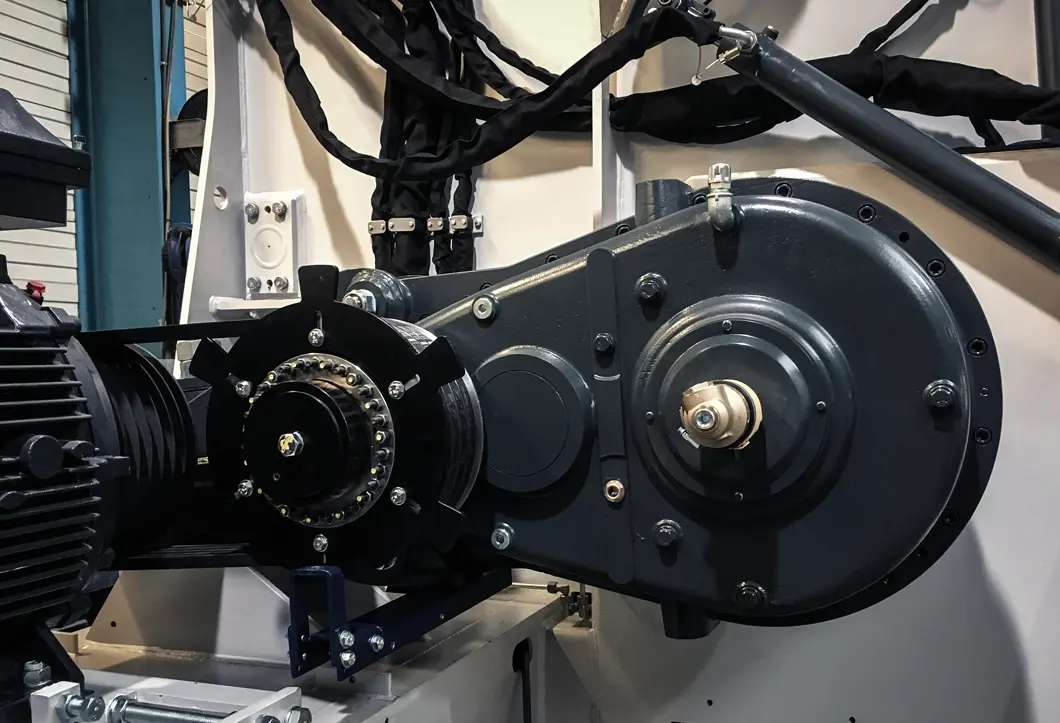

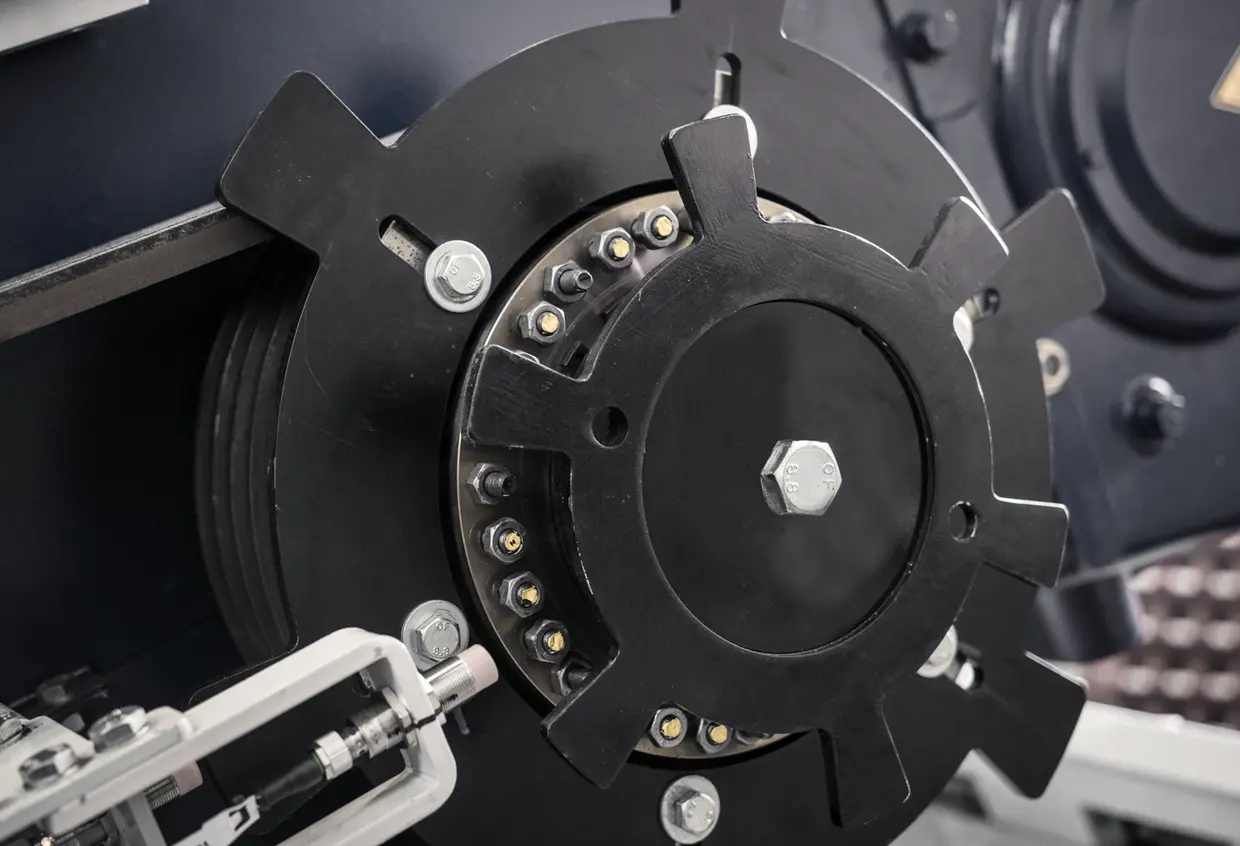

The Universo series with its robust, high-quality engineering ensures a long service life with consistently high throughput rates. Whether you are shredding different types of plastic or waste, with its heavy-duty gearbox drive and robust cutting system there is no job that this shredder cannot handle. As has been proven by thousands of operating hours in different fields of application.

Find Your Ideal Solution And

Connect With Us

Need answers about applications or particle sizes? Reach out today - our specialists are ready to provide support. Together, we'll uncover your perfect solution.

Input & Output Materials