Knows No Compromises.

Tried-And-Tested Quality Paired With Continuously High Output.

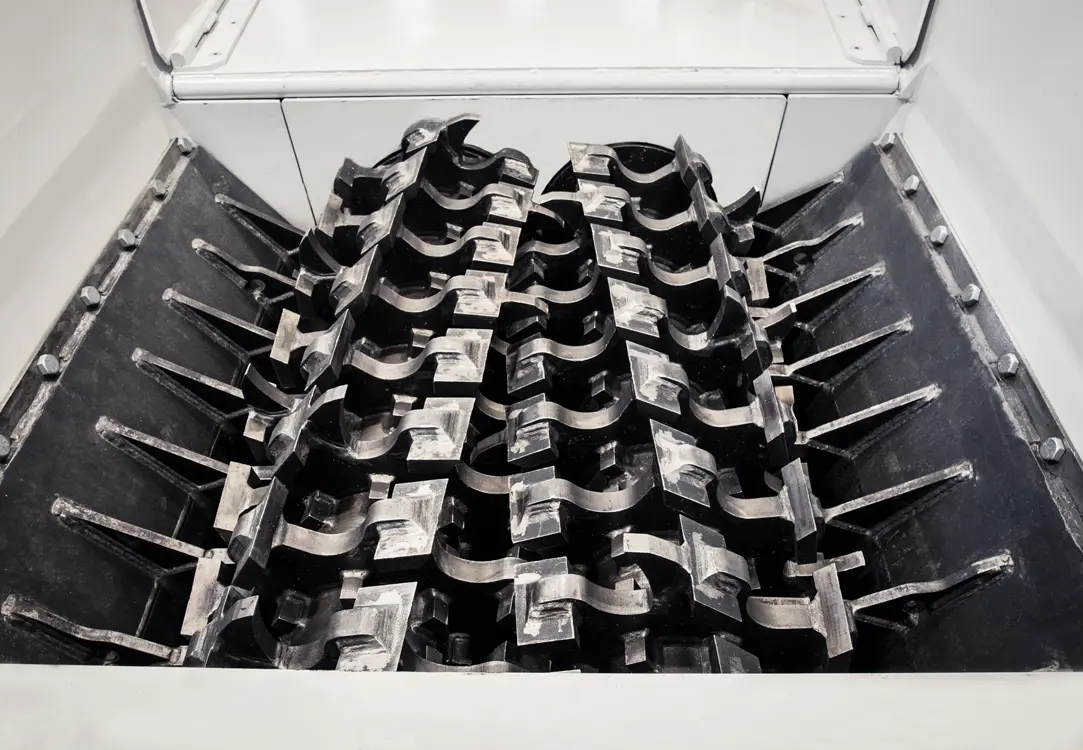

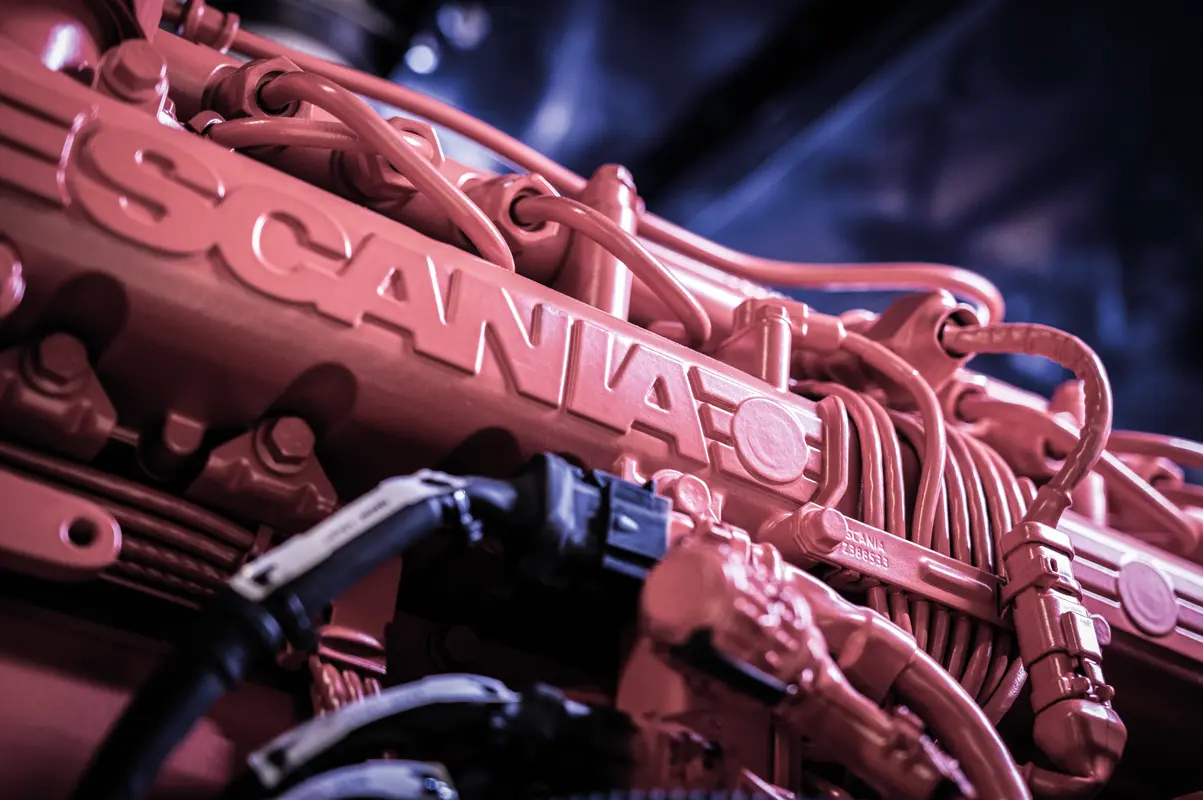

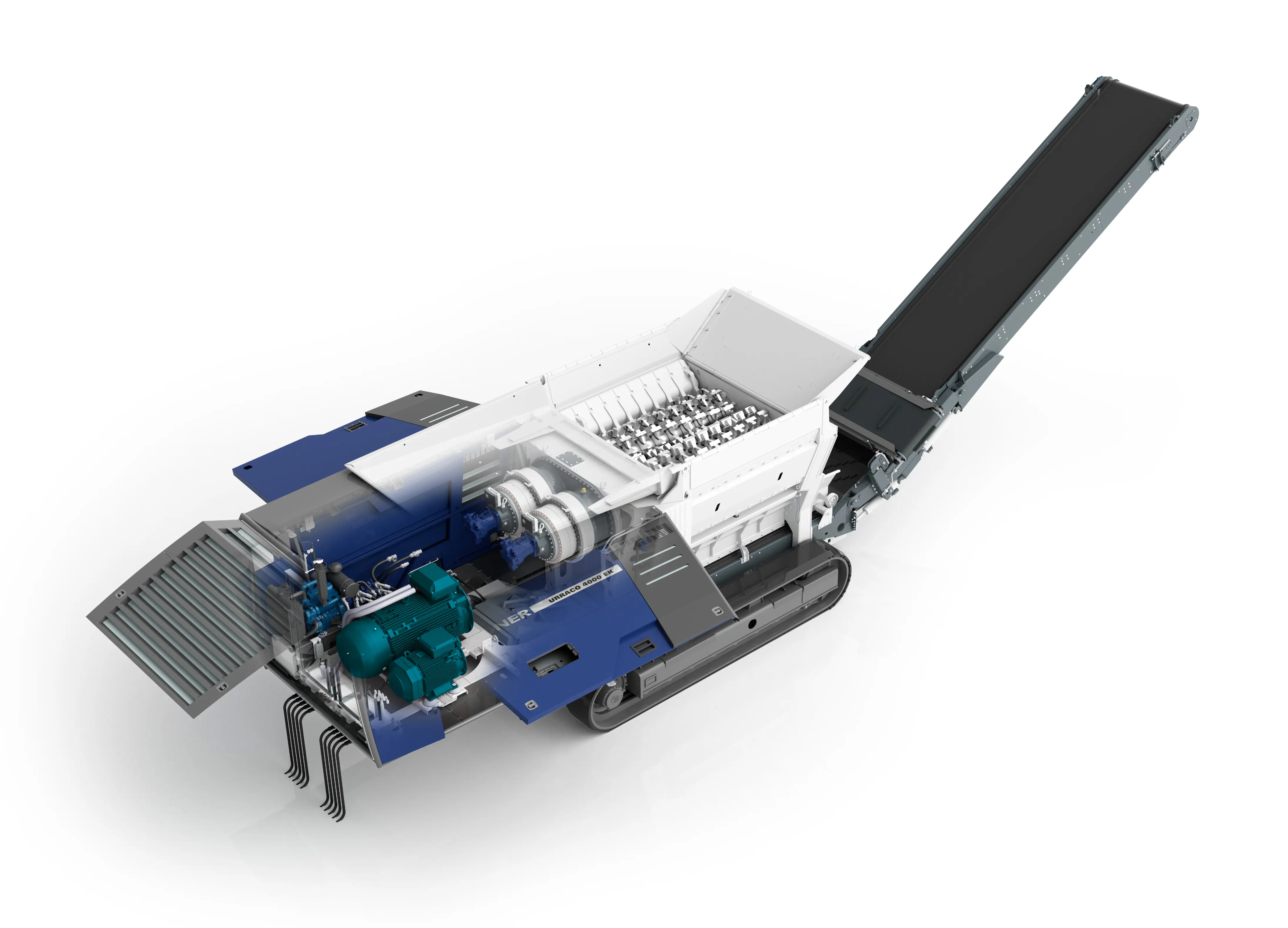

The Urraco 4000 series, Lindner’s new mobile shredder generation, leaves nothing to be desired in terms of mobility and the excellent accessibility to the maintenance points and the drive. The result: shorter downtimes, improved productivity and consistently high output. The E-models' independent power unit is particularly impressive since it makes it possible for the shredder to move easily to its next destination without any cables. The proven twin-shaft system in combination with the best intake performance shreds even bulky and high-volume materials smoothly, while the extended working area enables easy feeding by a wheel loader.

Connect With Us

Need answers about applications or particle sizes? Reach out today - our specialists are ready to provide support. Together, we'll uncover your perfect solution.

Input & Output Materials