Urraco 75D | DK | E

Wins Hands Down.

Gives You All the Advantages Of Mobile Shredding:

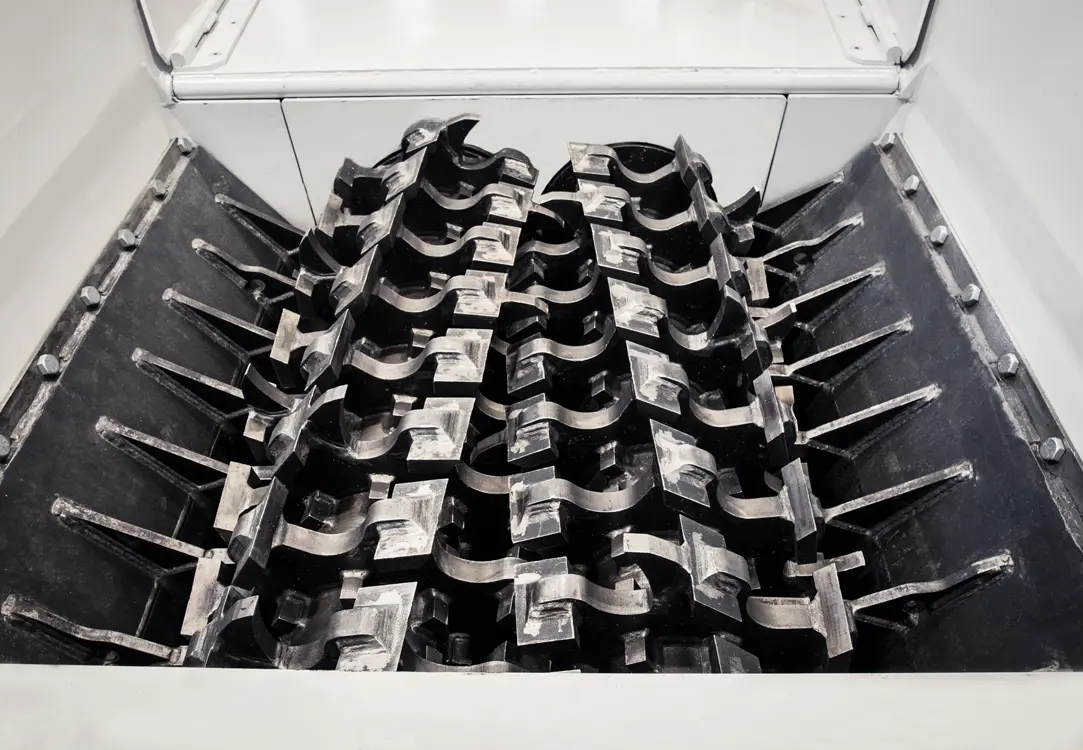

Compact, Yet Incredibly Strong.

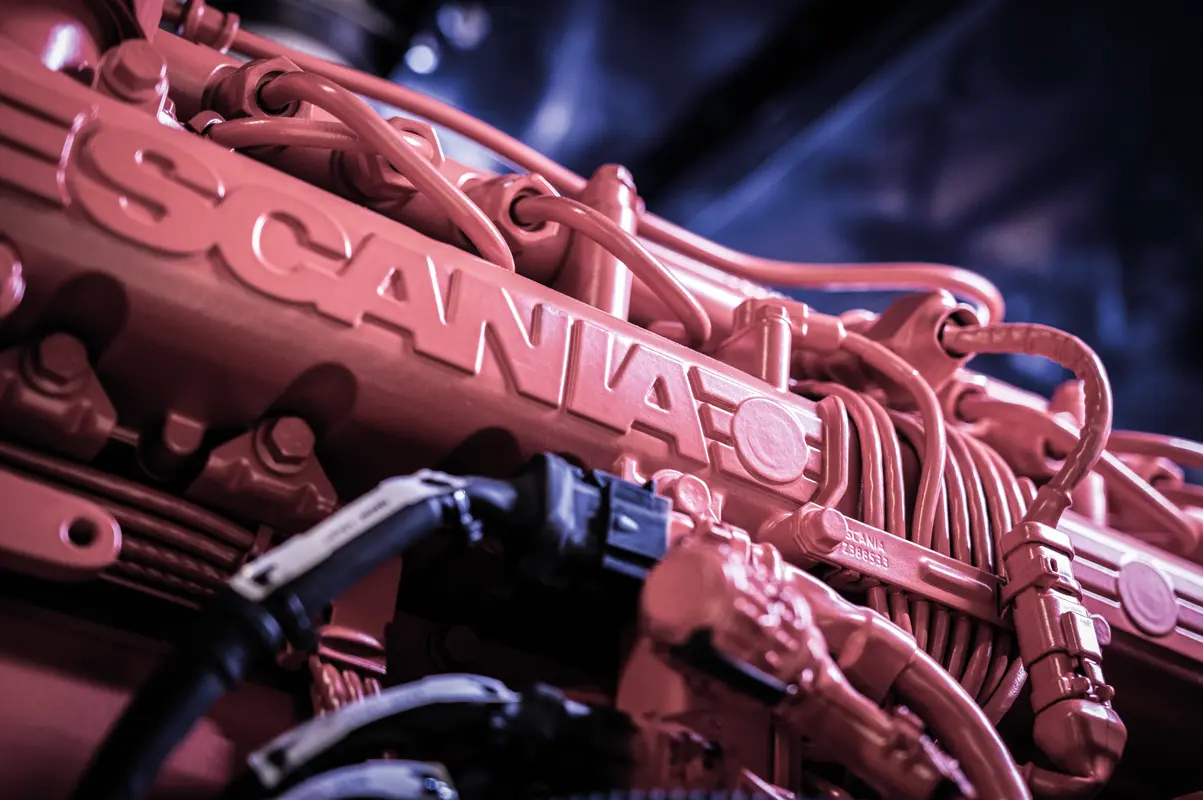

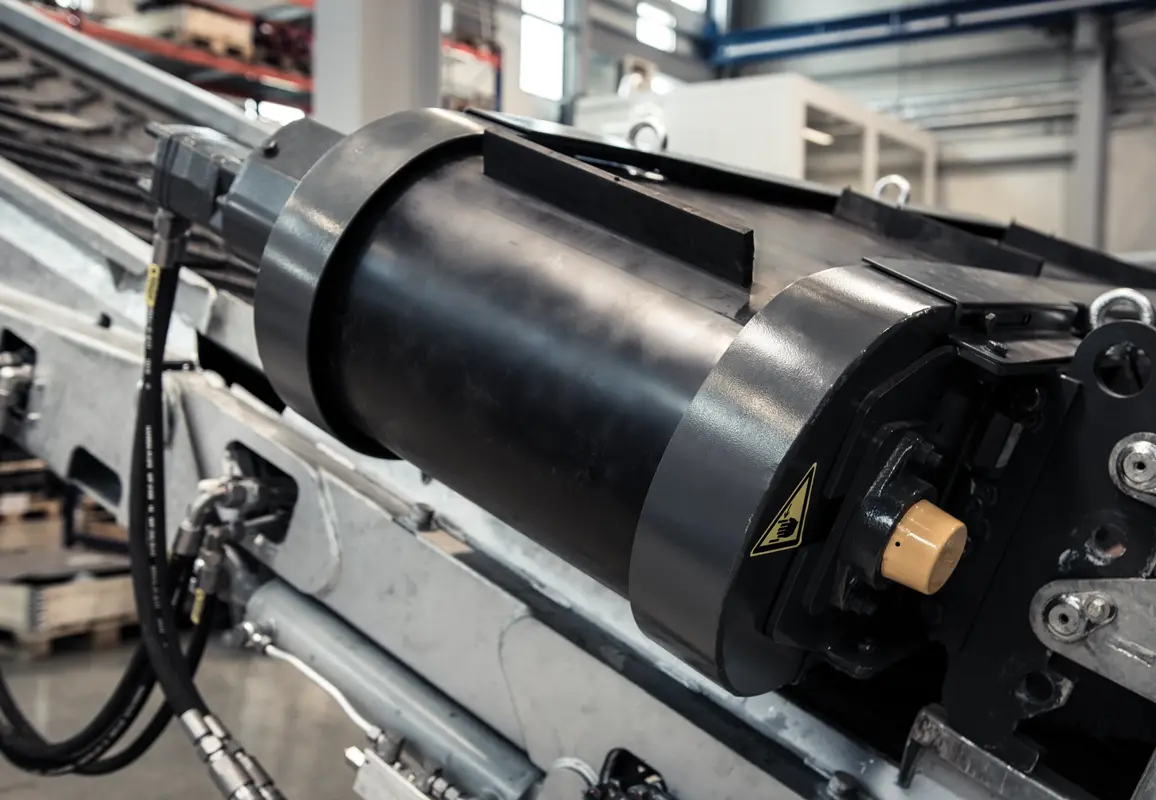

Robustly engineered and equipped with a powerful engine, the Lindner Urraco 75 shreds even difficult materials. Depending on the degree of mobility needed, the machine is available in two chassis versions: either with a wheel axle and tow bar, suitable for hook-lift transport and easy placing on the ground, or with a heavy tracked chassis for full mobility on site. Enjoy powerful shredding in an extremely compact form.

Find Your Ideal Solution And

Connect With Us

Need answers about applications or particle sizes? Reach out today - our specialists are ready to provide support. Together, we'll uncover your perfect solution.

Input & Output Materials