JUPITER 1800 | 2200 | 3200 | 2200 HP

Primary Shredding at Its Best.

Gets the Process Going:

Reliably High Output and Consistent Particle Sizes.

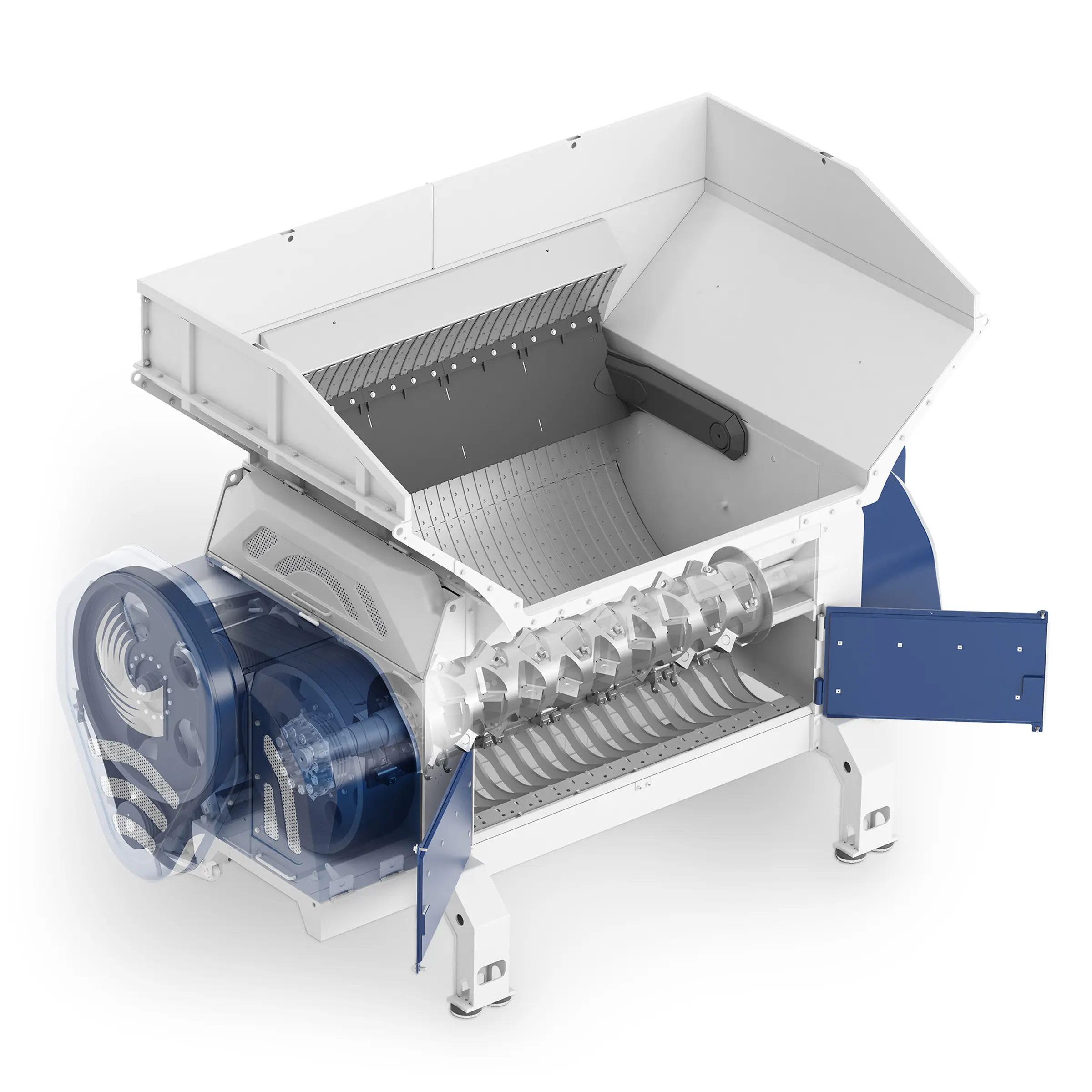

The Lindner Jupiter single-shaft primary shredder combines everything you need for efficient 24/7 operation: a powerful countershaft drive, a well-engineered machine design and high manufacturing quality. Undefeated by non-shreddables, our tried-and-tested technology ensures a long service life and low maintenance coupled with the necessary power to shred even the toughest materials – year after year and ton after ton.

Find Your Ideal Solution And

Connect With Us

Need answers about applications or particle sizes? Reach out today - our specialists are ready to provide support. Together, we'll uncover your perfect solution.

Input & Output Materials

Key Features

Lindner Advantages

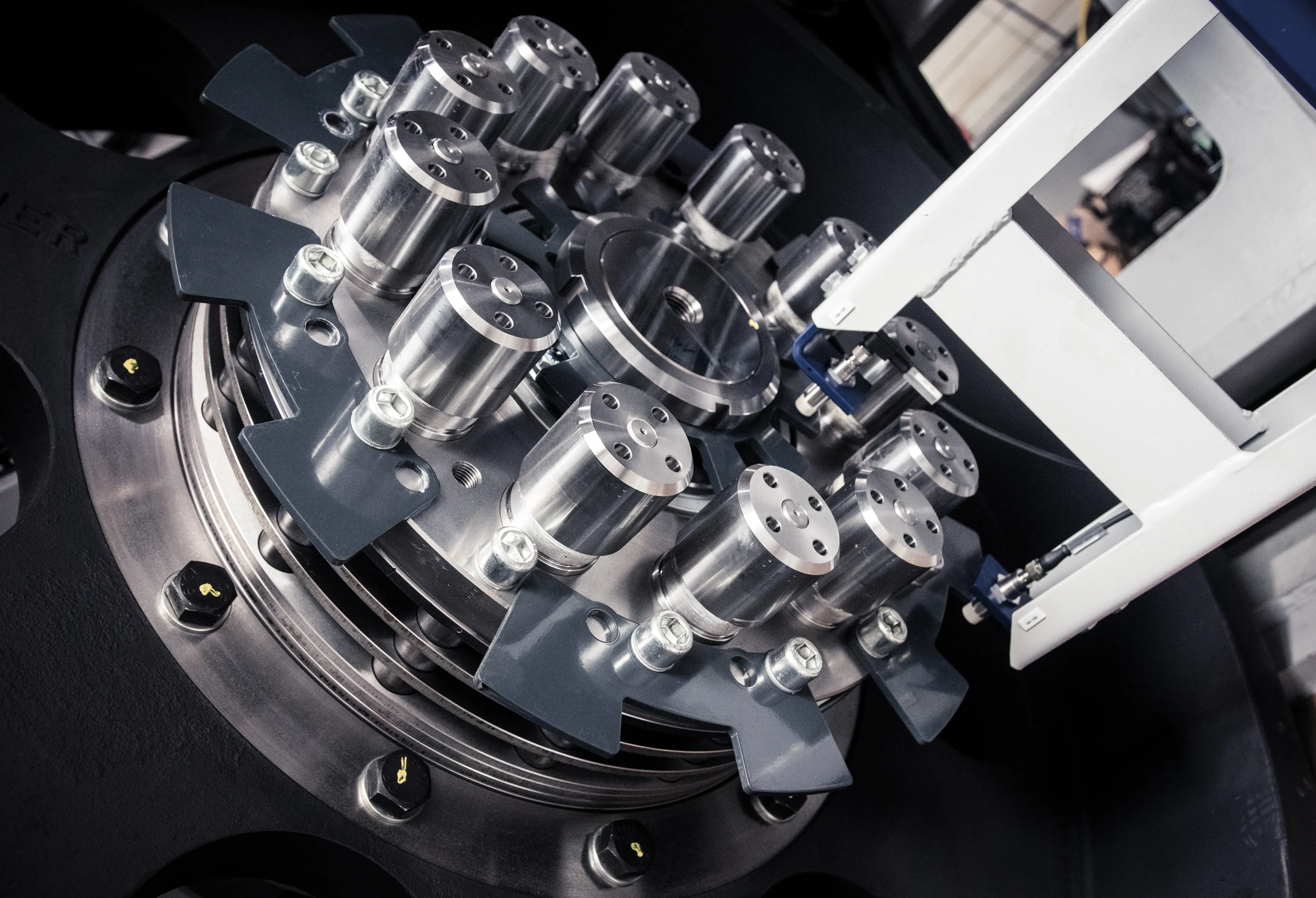

Single-Shaft Cutting System With Four-Fold Useable Pointed Knives

- Solidly built knives and knife holders particularly resistant to non-shreddables

- Maximum availability, as knives can be changed quickly

- Easily adjustable cutting gap for optimum output quality

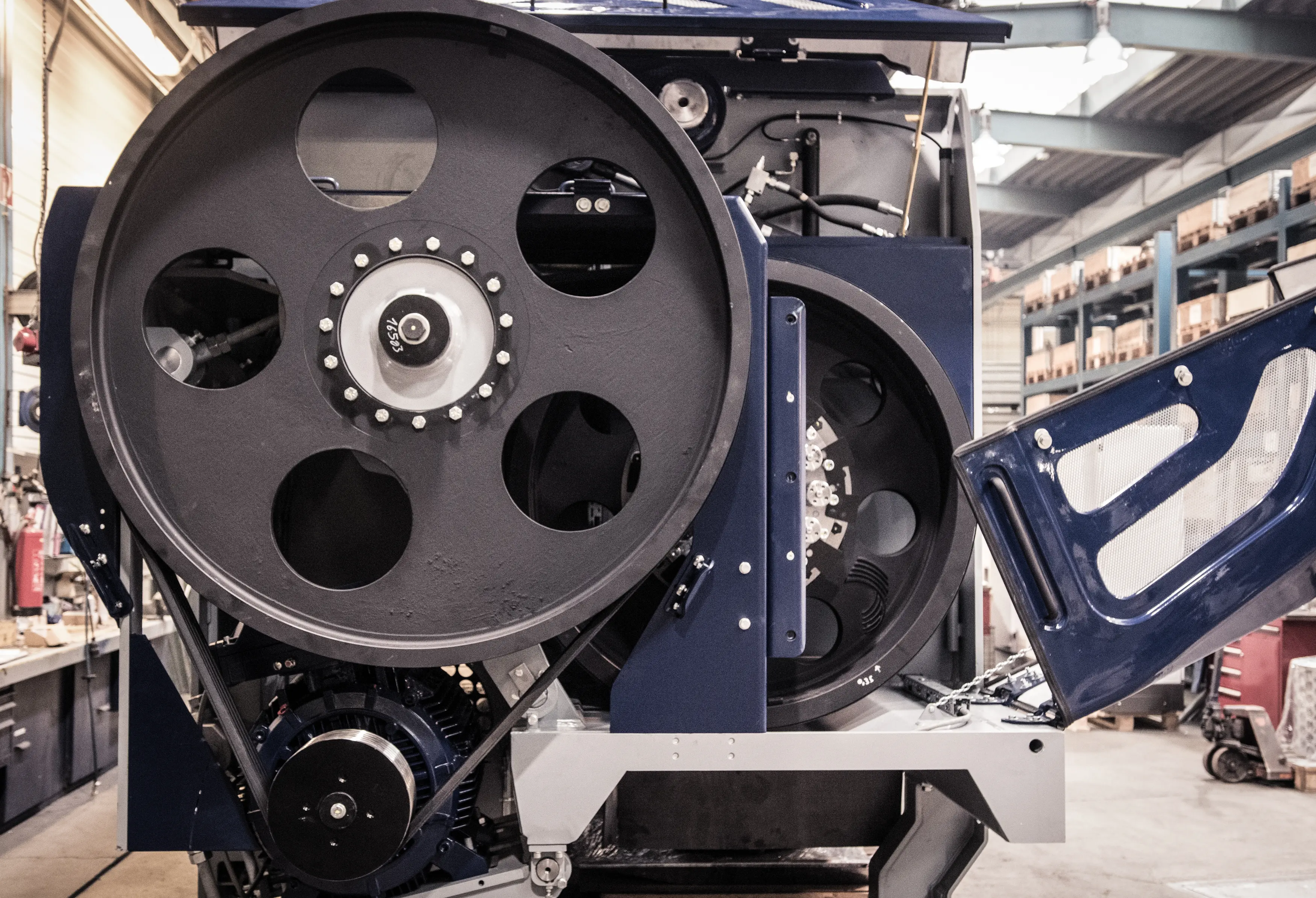

Countershaft Drive With Flywheel Energy Storage

Less energy consumption and more power thanks to the countershaft drive that stores and releases rotational energy depending on the load.

- Highest energy efficiency

- Consistently high throughput even with tough materials

- Spare parts obtainable worldwide

- Also available as a HP model (high performance model) for even more power and throughput