Really Packs a Punch.

Productivity From Start to Finish.

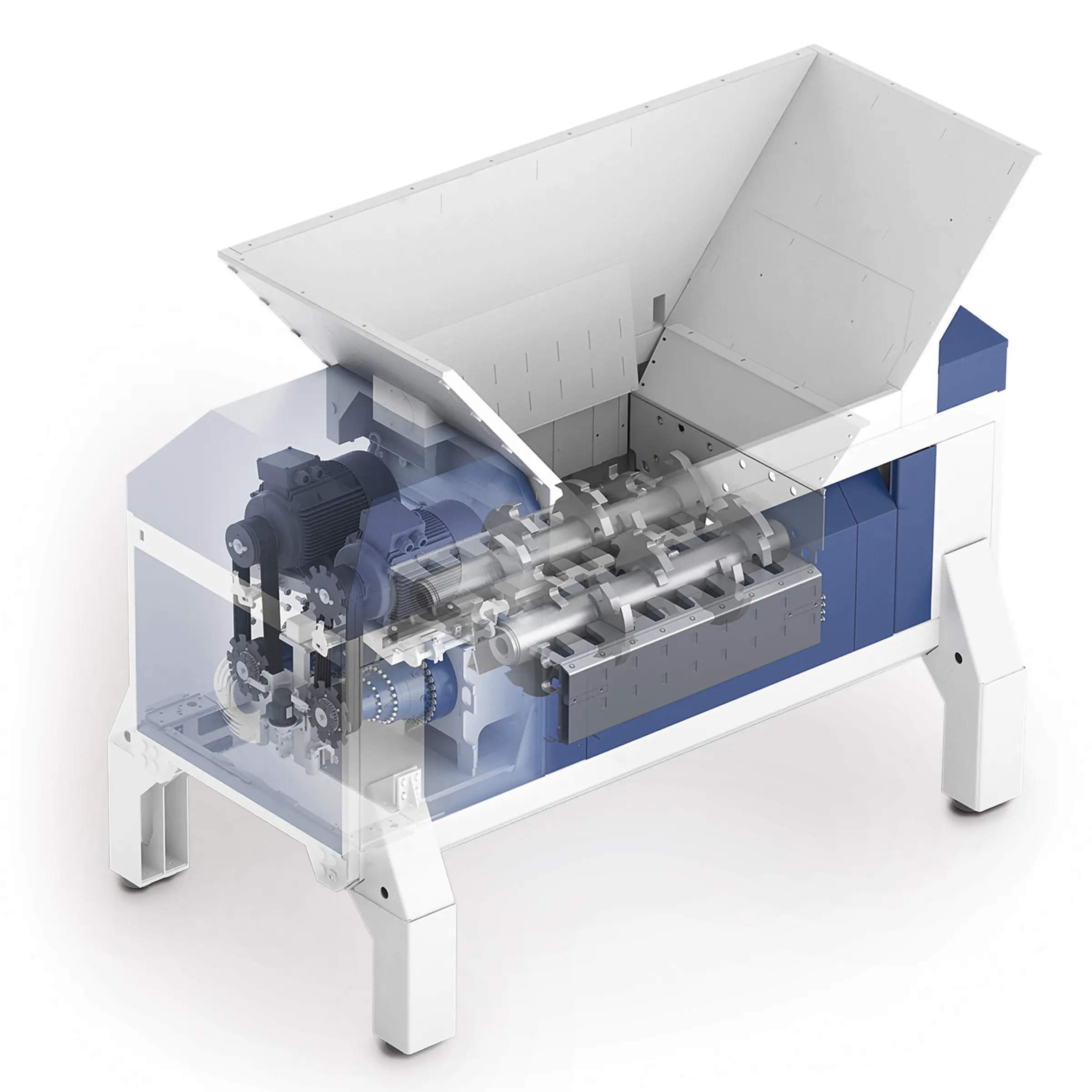

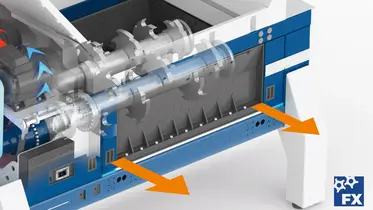

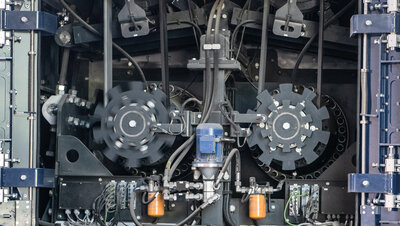

Based on the proven belt concept, the Lindner’s Atlas 5500 AS twin-shaft primary shredder sets new efficiency standards with its high-performance planetary gears, innovative DEX (Dynamic Energy Exchange) energy recovery system and asynchronous shaft control. Delivering consistently high throughput, built for tough applications and equipped with the innovative FX fast exchange system, this shredder provides maximum uptimes and can be relied on to keep the line going.

Connect With Us

Need answers about applications or particle sizes? Reach out today - our specialists are ready to provide support. Together, we'll uncover your perfect solution.

Input & Output Materials

Lindner Advantages

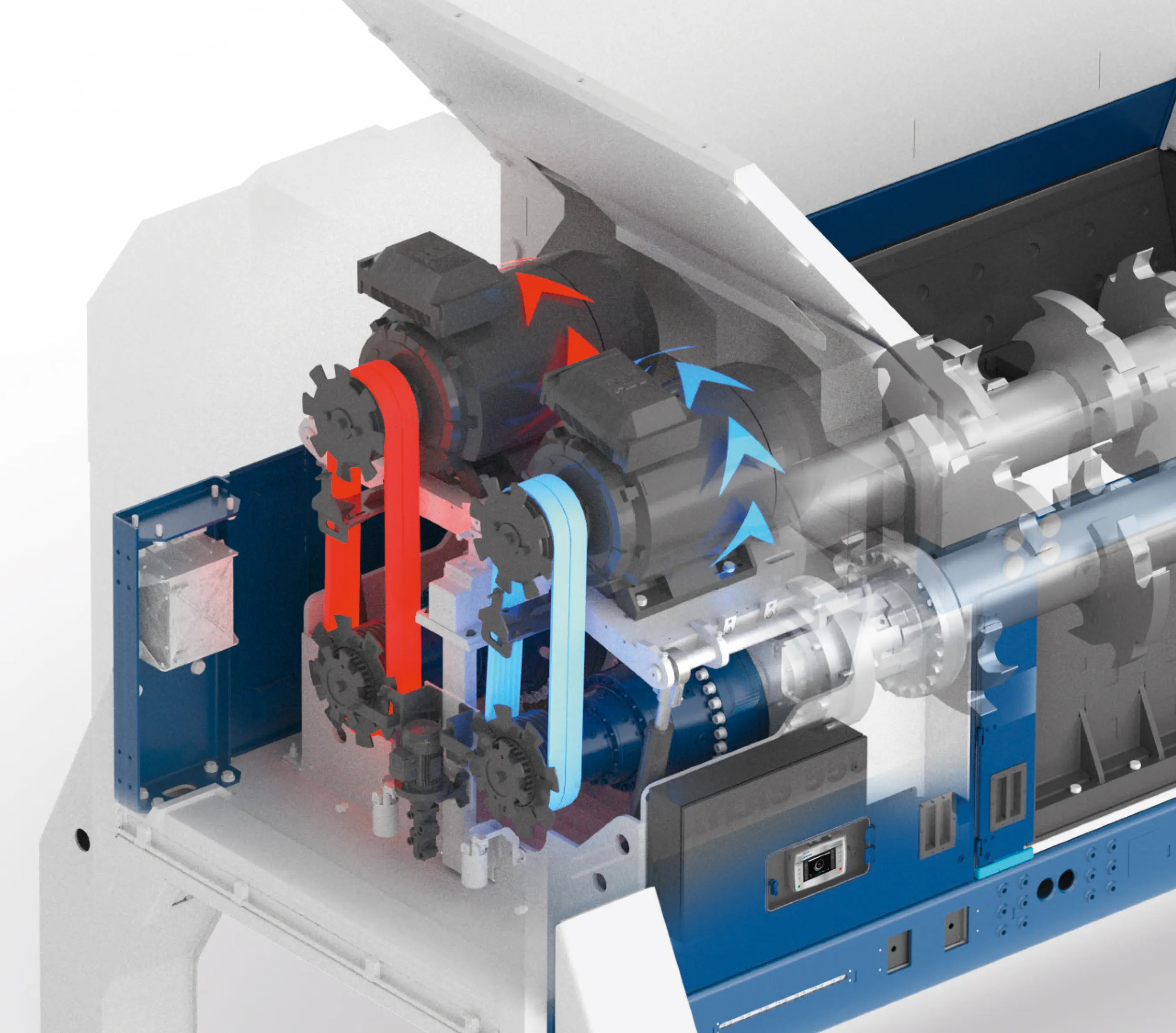

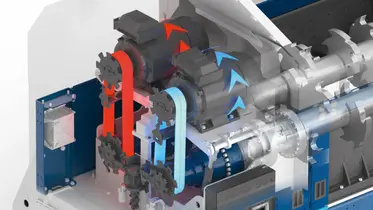

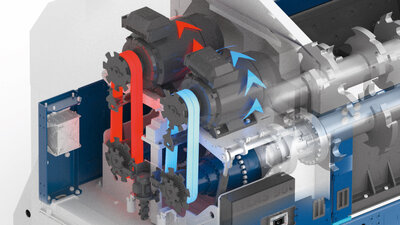

Lindner's Dex - Dynamic Energy Exchange System

For Maximum Efficiency

Maximum efficiency is achieved by actively using braking energy when reversing one of the shafts. Top productivity is ensured with an instant, power electronics-con-trolled reversal of the shaft running direction.

- Innovative, load-dependent energy management

- Highest energy efficiency in operation

- Maximum agility while changing the running direction, up to 3 times faster

Drive Unit With Convenience & Maintenance Functions (Optional)

LINDNER’S ATB – AUTOMATIC BELT TENSIONING SYSTEM:

- Ensures optimum power transmission at all times

- Belt exchange using a hydraulic tensioning device

- Self and preventive monitoring

COMPRESSED AIR VENTILATION DRIVE UNIT:

- Protects the drive unit from dirt

- Significantly reduced maintenance activities

- With radial fan and self-cleaning function

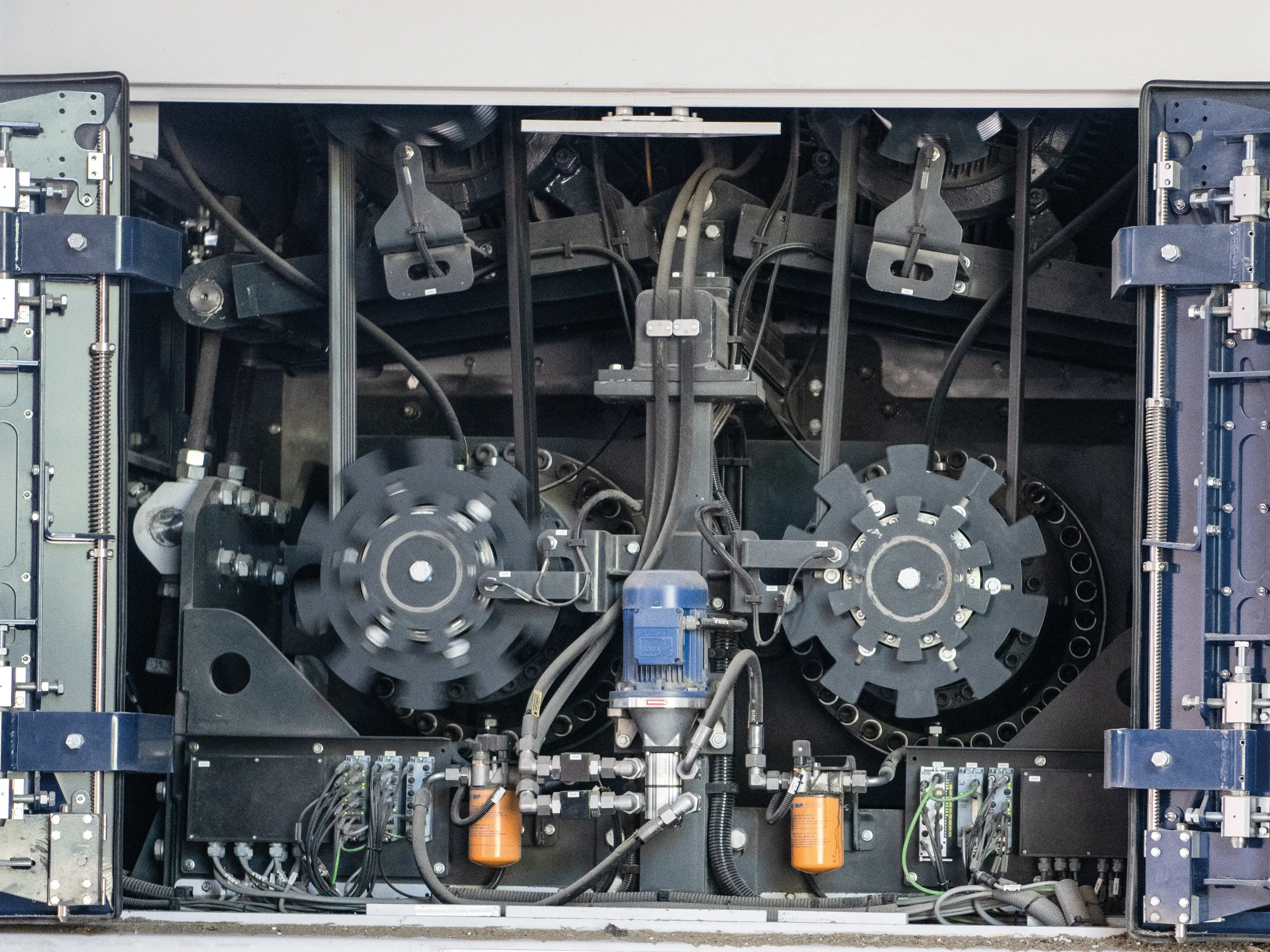

Asynchronous Twin-Shaft Cutting System

The cutting system of the Atlas AS consists of two asynchronously running, fully welded rotors and a solid scraper unit. The asynchronous ripping (ripping apart, ripping up) at low speeds with high torque combined with the dynamic energy recovery enables:

- Aggressive material intake

- Continuous volume flow

- Highest productivity

- Ideal output material for sorting