Spittal an der Drau, June 2023. On 22 June 2023, the Lindner family business invited long-time associates and partners to the official opening of the new company headquarters in Spittal/Drau, Austria. In addition to that the company celebrated its 75th anniversary and the 10th anniversary of its subsidiary Lindner Washtech. As part of the opening celebrations, visitors were given exclusive insights into the state-of-the-art production facilities.

Make the most of waste. Committed to the circular economy and transforming waste into new raw materials, recycling pioneer Lindner has been exporting shredders and recycling plants all over the world for 75 years. Whether it be in South Korea, the US, Brazil, Italy, Sweden, Germany or Austria – recycling solutions from Lindner are often considered to be the benchmark in the industry. Solutions from Lindner process household waste, industrial and commercial waste, plastics, waste wood and light metals into new recyclable raw materials. Since the company was founded, shredders and system solutions have been planned and manufactured in Spittal an der Drau in Carinthia. “The positive market development coupled with the increasing demand for Lindner quality products led to our decision to construct a new plant in 2019 and so to invest around 48.5 million euros. “This turned out to be an important strategic step,” emphasises Manuel Lindner, owner and Managing Director of Lindner-Recyclingtech GmbH. “In many ways, 2023 is a historic year for us. We want to celebrate the two company anniversaries as well as the successful move to our new home of recycling together with our long-time supporters and customers.”

Automation & Sustainability

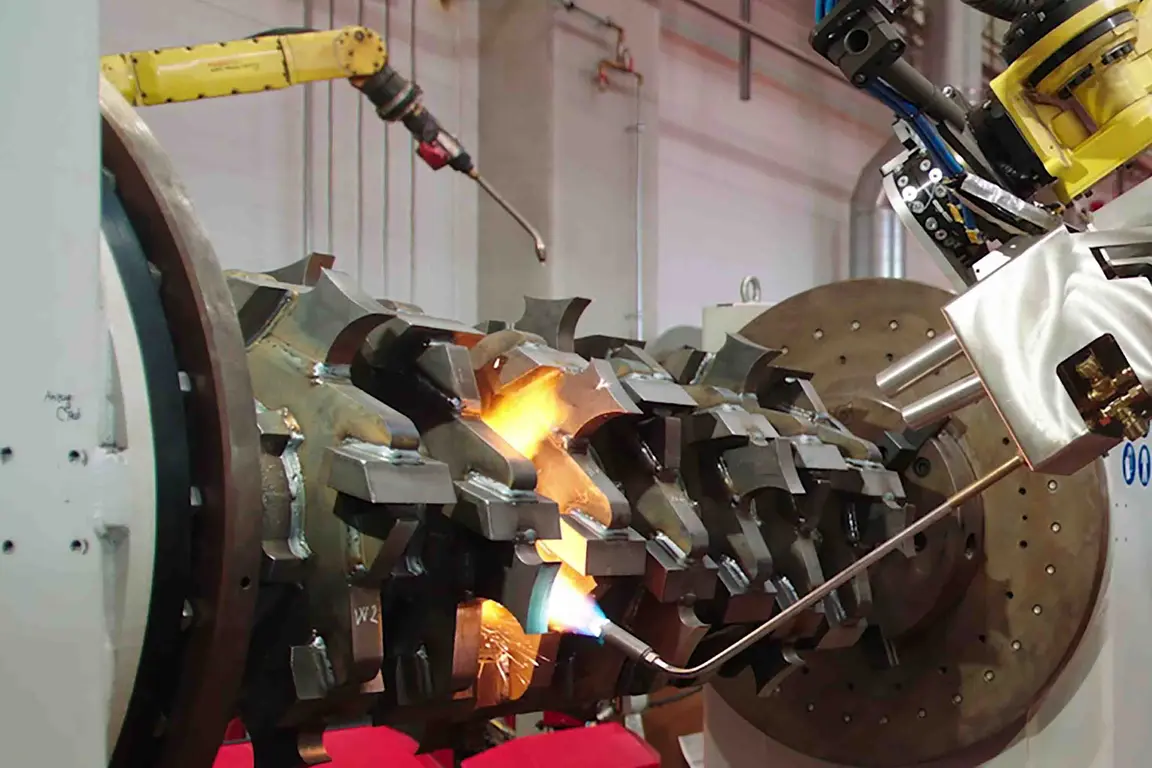

With the new plant, the production area has more than doubled in size to 14,000 m². “The high demand for our machines goes hand in hand with a capacity increase – hence why we decided to double the production area. The further expansion of robotics and automation technology in the welding workshop and machining production is just as crucial here, because if we want to finish more machines in assembly, we also require more individual components. Thanks to the new production technologies, we can now manufacture a lot of the machine parts ourselves, which is very convenient for us, especially when supply chains are interrupted,” explains Manuel Lindner. “By expanding high-tech automation and robotics, we can also offer our employees a better workplace. Physically strenuous work, which was sometimes necessary when loading machines, is no longer required. The focus has now switched to the expert operation of the production machines. We were also able to create a pleasant atmosphere for our employees in the office building with the new bright and friendly rooms,” adds Michael Lackner, Managing Director at Lindner.

Investing in the new plant by optimising the machine throughput times, increasing the in-house production range, and expanding automation, robotics and quality assurance, also means investing in the future.