Goes It Alone.

Cost-Efficient, Highly Reliable And Only One Step.

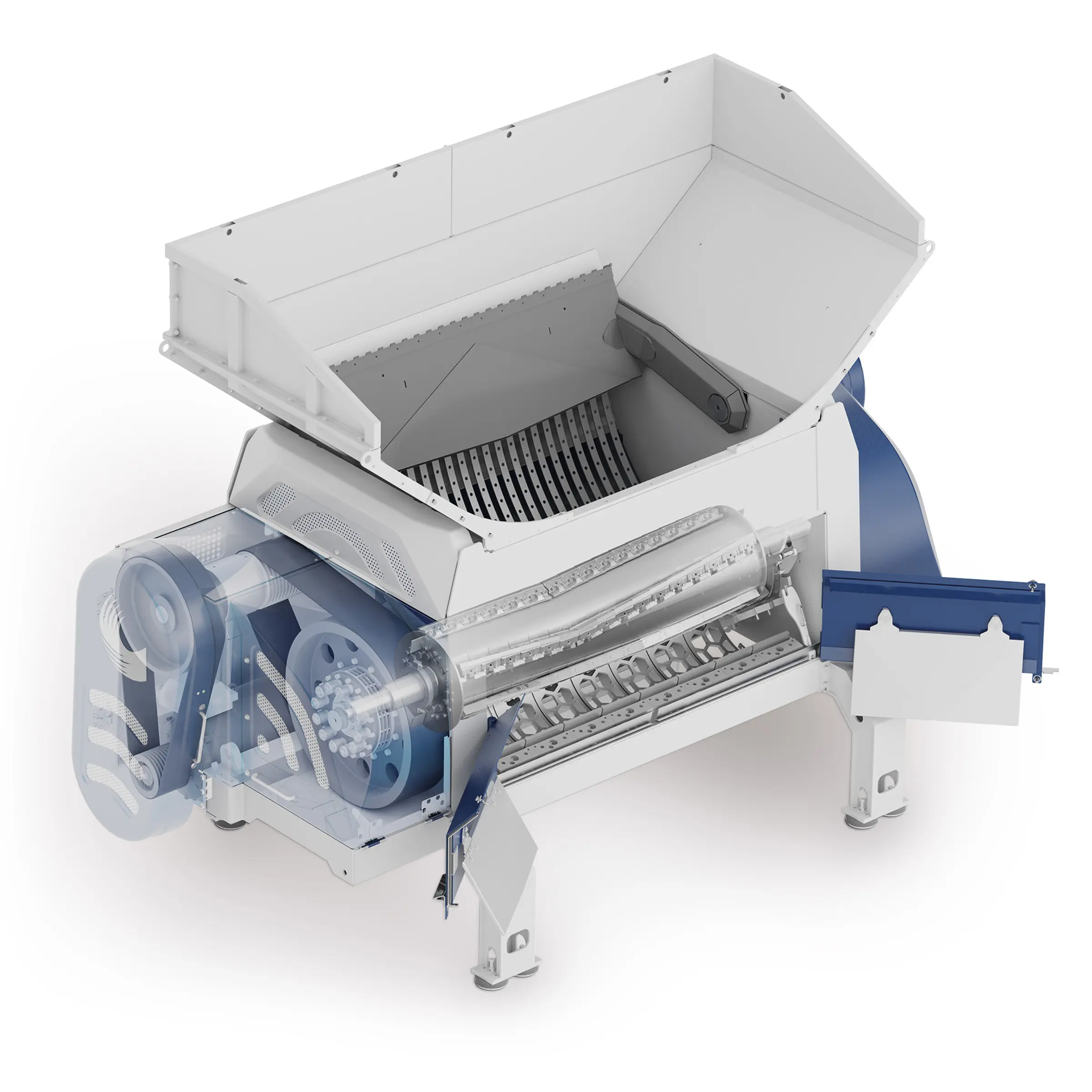

Nothing can withstand the enormous power of the Lindner Polaris single-shaft shredder. Made for one-step processing of untreated municipal, industrial and commercial waste to obtain mid-calorific fuels (40 - 120 mm) ideal for co-incineration in calciners at cement works. Sturdy design and low operating costs are the hallmarks of this highly specialised shredder: enjoy uninterrupted shredding excellence 24 hours a day, seven days a week. With maximum efficiency throughout, as demonstrated by a field test: thanks to the countershaft drive, the Lindner Polaris shreds twice as much material as comparable machines in the same period of time.*

Connect With Us

Need answers about applications or particle sizes? Reach out today - our specialists are ready to provide support. Together, we'll uncover your perfect solution.

Input & Output Materials

Lindner Advantages

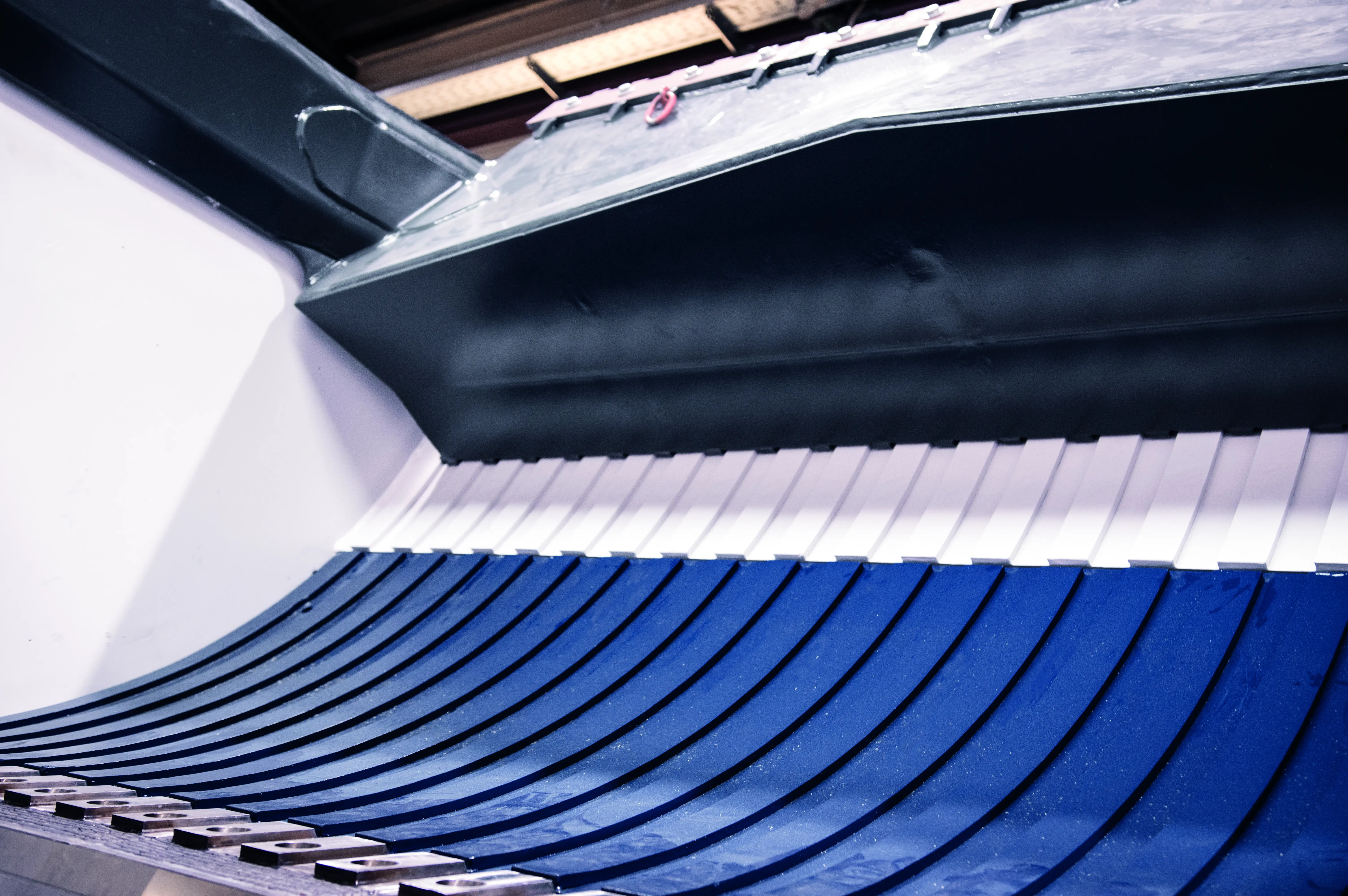

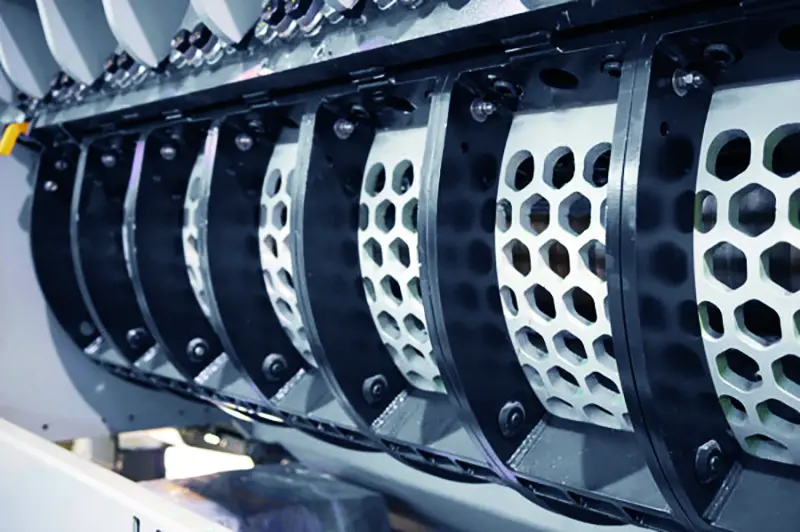

Single-Shaft Cutting System With Four-Fold Usable Solidly Built Square Knives

- Parts storage made easy thanks to identical knives for the rotor, counter knives and scraper

- Maximum uptimes ensured by four-fold usable, quick-change knive

- Low wear part costs thanks to four-fold usable square knive

- Easily adjustable cutting gap – even during operation – for consistently, high-quality output

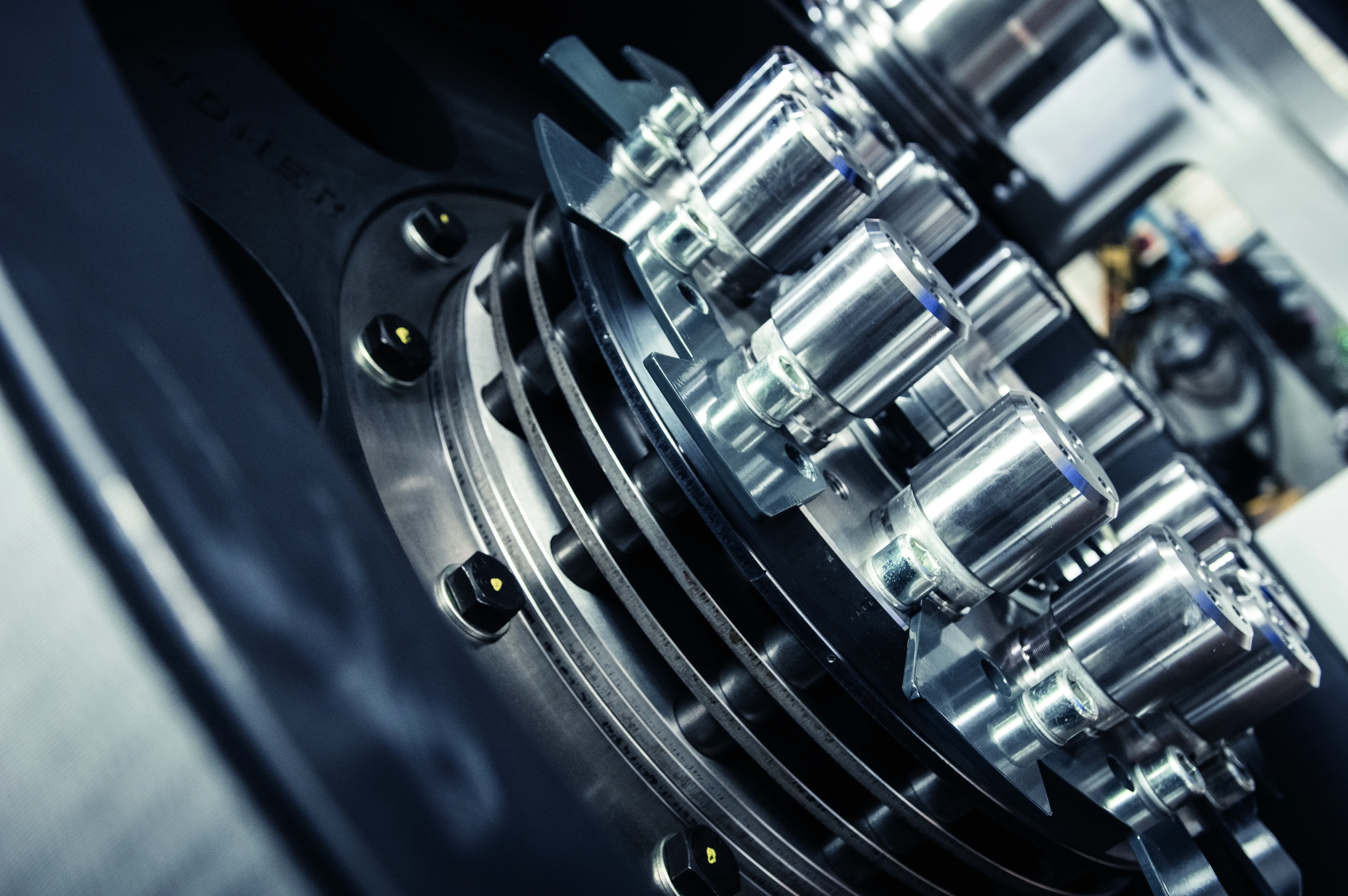

Countershaft Drive With Flywheel Energy Storage

Less energy consumption and more power thanks to the countershaft drive that stores and releases rotational energy depending on the load.

- Maximum energy efficiency

- Up to 2 x more throughput compared to drives without higher flywheel mass*

- Spare parts available worldwide

*University of Leoben, (2017). Independent report on the performance of different drive systems for shredding machines.