Never Loses Out.

Super Special, For Maximum Productivity.

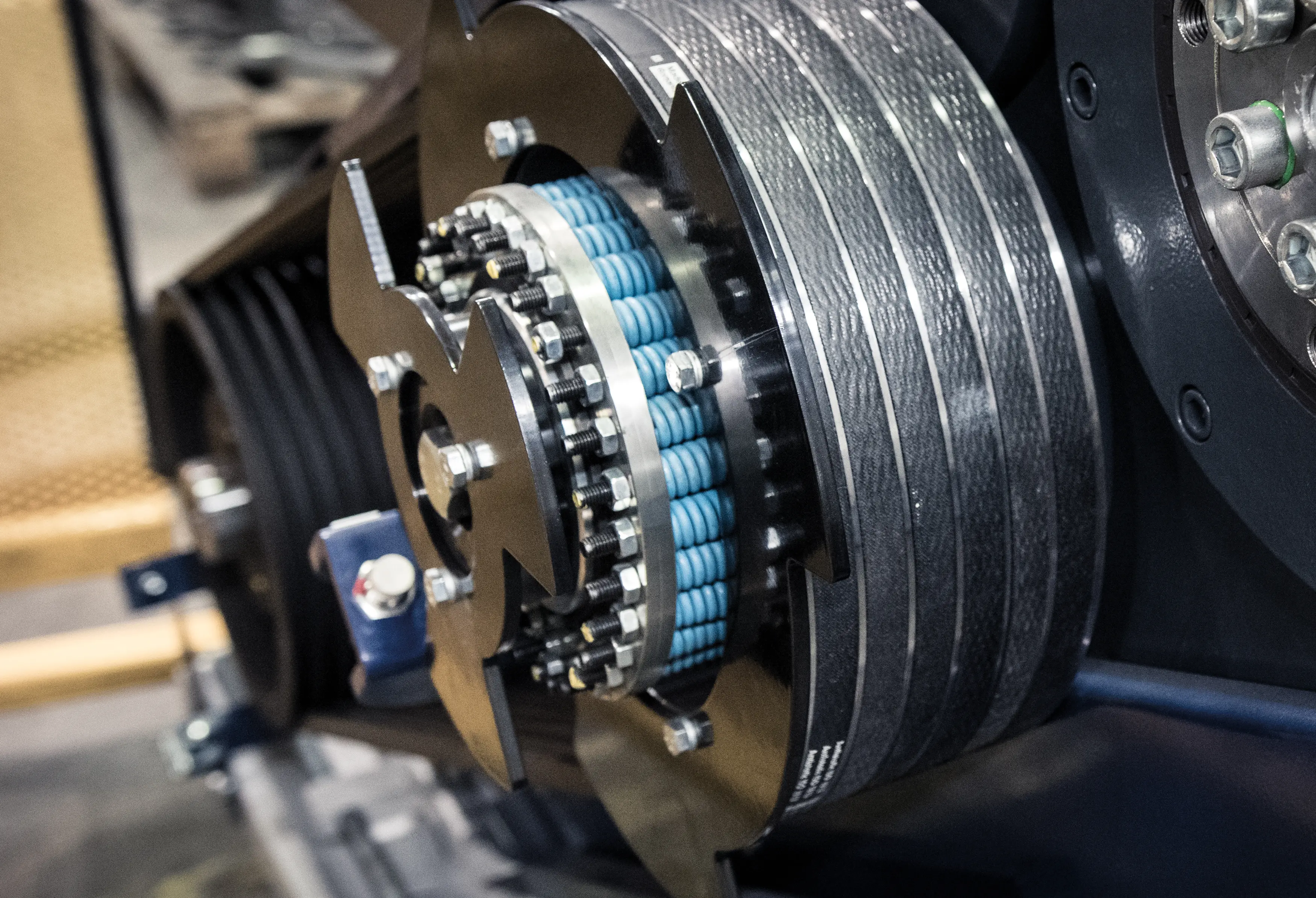

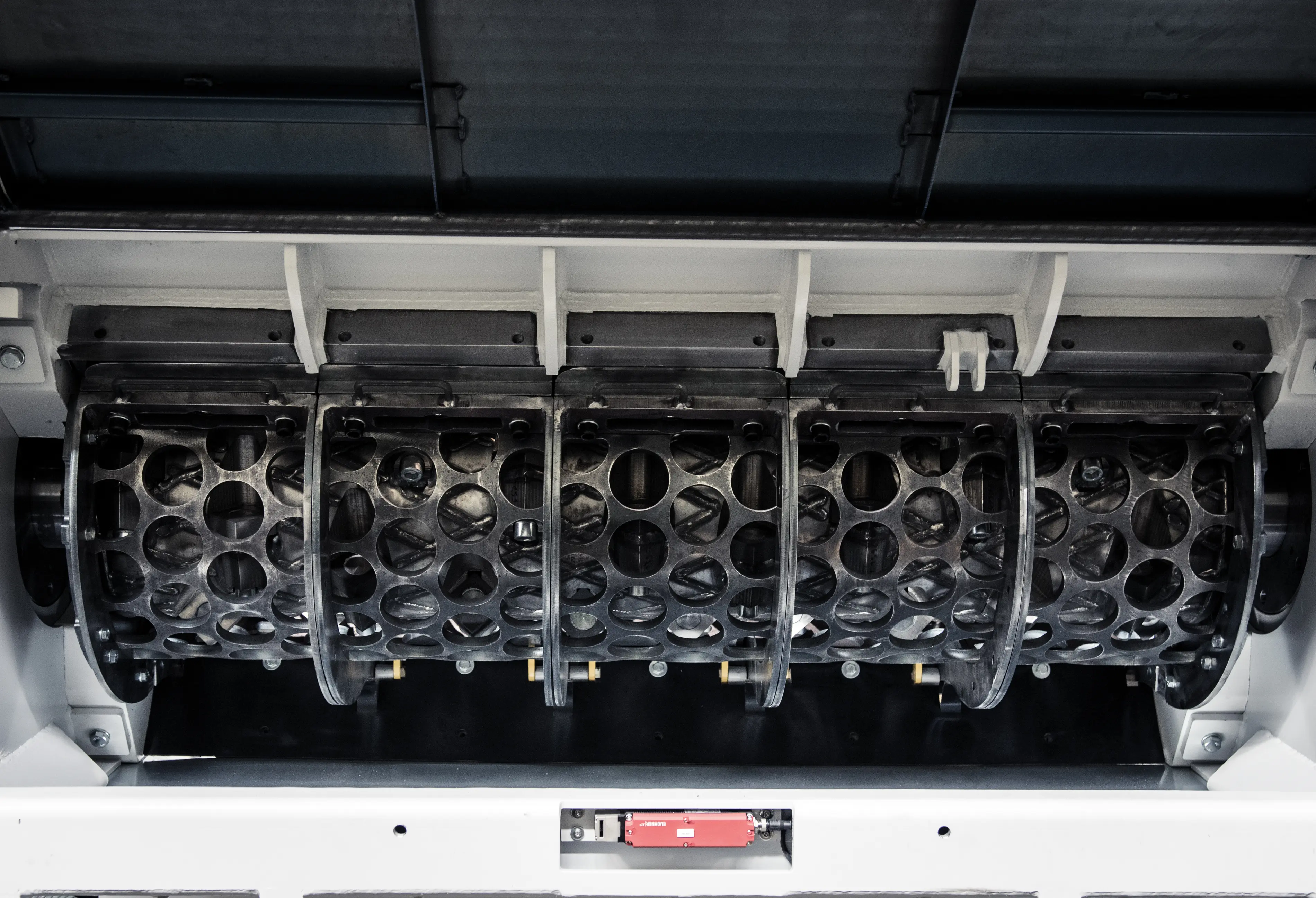

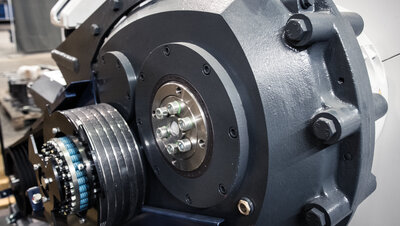

The single-shaft shredder in combination with its powerful gear or direct belt drive and its unique Mono Fix technology make the Micromat series the benchmark for shredding post-consumer or industrial waste. The Lindner Mono-Fix system allows knives and knife holders to be changed with just a single screw. Different pointed and flat knives as well as blind plates and special counter-knives can be used on the same rotor body - so the cutting system can be easily and effortlessly adapted to different input materials, which in turn has a positive effect on quality and throughput.

Connect With Us

Need answers about applications or particle sizes? Reach out today - our specialists are ready to provide support. Together, we'll uncover your perfect solution.

Input & Output Materials

Lindner Advantages

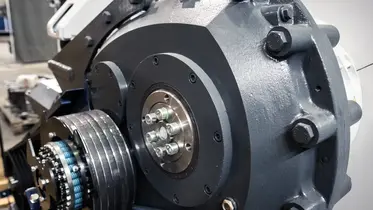

Flexible Cutting System

The Antares’ individually configurable cutting system with pointed knives ensures maximum output while taking up minimum floor space. The cutting system is designed with various applications in mind, ensuring efficient shredding of a wide range of materials.

- Optimum output thanks to knife configurations that can be individually adapted to the requirement

- Low wear and tear thanks to the optional hardfacing of rotor and knife holders

- Consistent particle size with a cutting gap that is adjustable

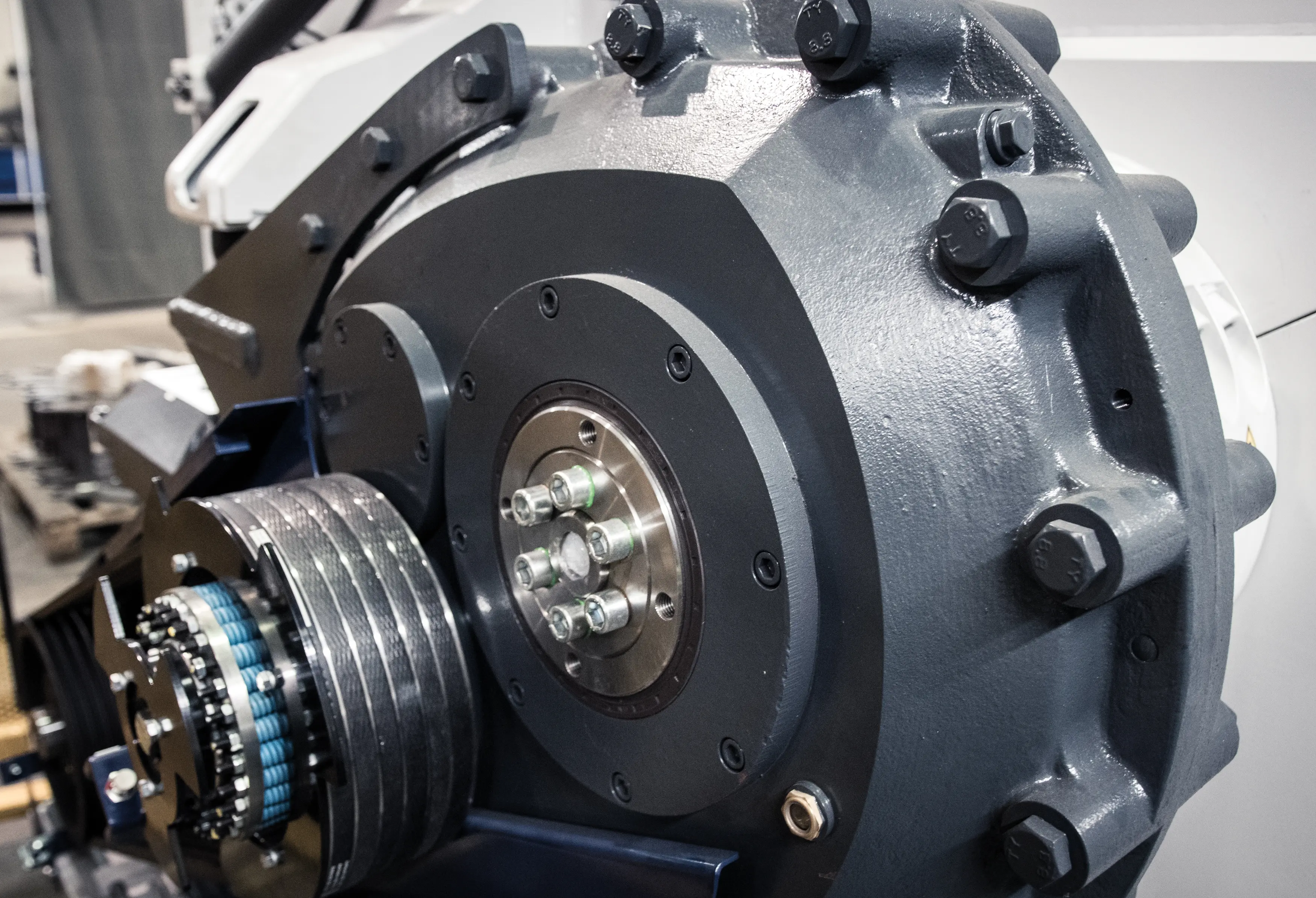

Robust Gear Drive

- Powerful shredding due to powerful motors with high torque

- Individual adaptation to the material through variable speeds

- Worldwide availability of the easy-to-change standard components