The company Lohner Kunststoffrecycling GmbH (LKR) in Vechta, Germany, has been recovering plastic waste generated during the production of industrial or consumer goods since 1992. The highly specialised pioneer and full-service provider is now part of the Remondis Group and transforms about 45,000 metric tons of rejects into new material every year – a perfect example of a circular economy. When it comes to shredding, the company relies on Lindner Recyclingtech’s state-of-the-art solutions such as the Micromat 2000. Equipped with the latest Multiplex cutting system, the machine efficiently shreds almost any type of plastic. The productivity gains, even for difficult materials such as sheets or pipes, are astonishing.

Today the disposal of production waste is a no go. International discussion is driving medium-sized companies and even large industrial and consumer goods manufacturers to use raw materials more sustainably. And from an economic point of view, it is absurd to simply dispose of valuable recyclable materials. As a circular economy pioneer, LKR knows that there is far more to it when people talk about recycling plastics. Mechanical recycling requires specialist knowledge, not least about the various types of polymers used in its manufacture.

Besides classic purges from injection moulding machines, other parts also need to be recycled, such as pipes or profile sections, punching waste and various plastic types like polypropylene (PP) or polyethylene (PE-HD, PE-LD). Hundreds of thousands of tonnes of these secondary raw materials have already been processed in Vechta. To keep productivity high, the company relies on Lindner's expertise and technology. In addition to other equipment from the manufacturer of shredders and system solutions for waste processing, a Micromat series shredder with the latest Multiplex cutting system is also in use. This system was specifically developed for shredding a wide range of materials at high output rates. Due to the unit’s special geometry, the rotor knives actively pull in the material. Combined with the powerful drive, this ensures up to 40% higher throughput for the same machine size – virtually irrespective of the type of plastic being shredded.

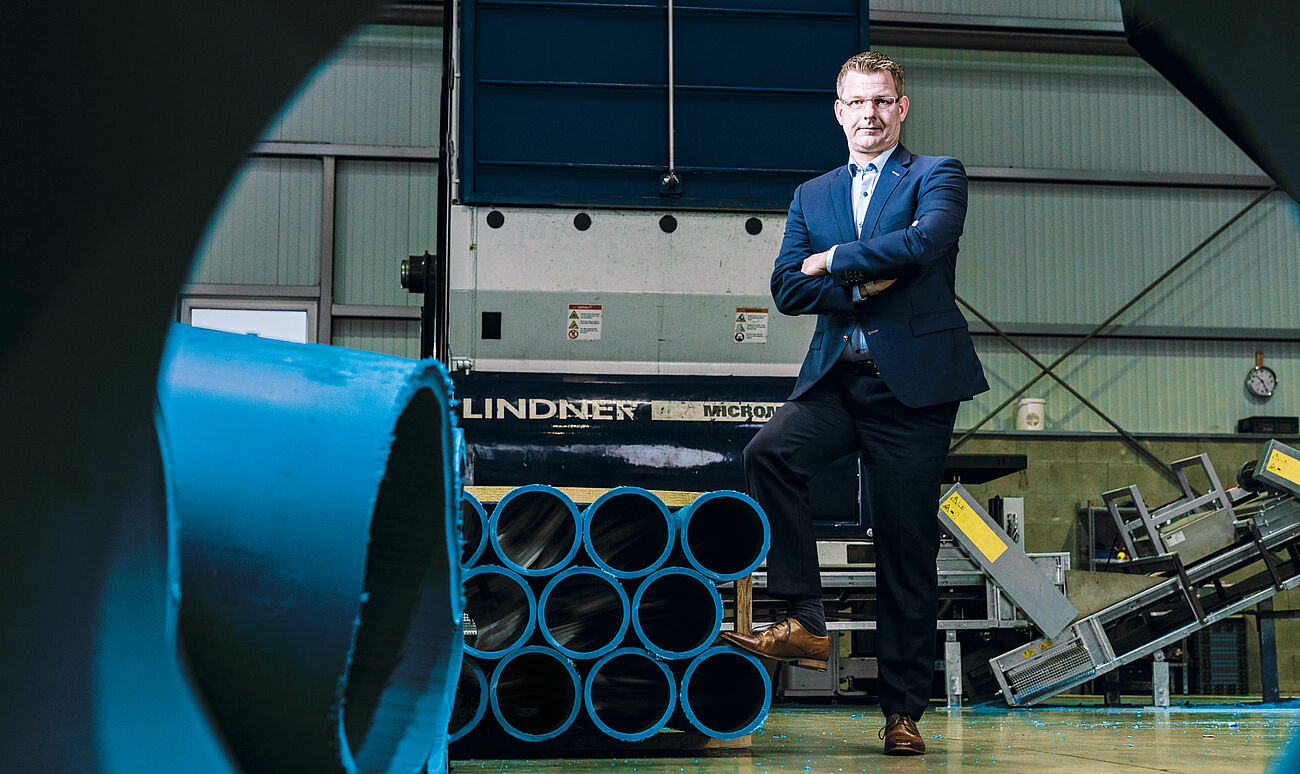

Jan-Hendrik Wilming (on the picture), CEO at LKR, also confirms this incredibly positive development: ‘When producing high-quality, homogenous recyclates, productivity and the flexibility of the equipment are key. This is why we at LKR have been using Lindner machines for a very long time. Now, with the Micromat's innovative cutting system, we have been able to significantly increase throughput once again, even with tough materials, and without having to switch to a larger shredder.’